W

WA barring engine is a small engine that forms part of the installation of a large engine, and is used to turn the main engine to a favourable position from which it can be started. If the main engine has stopped close to its dead centre it is unable to restart itself. Barring may also be done to turn the engine over slowly (unloaded) for maintenance, or to prevent belt drives being left too long in one position and taking a "set".

W

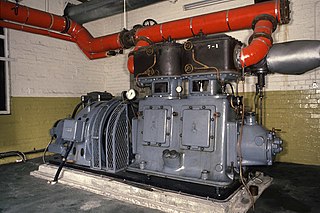

WA blowing engine is a large stationary steam engine or internal combustion engine directly coupled to air pumping cylinders. They deliver a very large quantity of air at a pressure lower than an air compressor, but greater than a centrifugal fan.

W

WA Corliss steam engine is a steam engine, fitted with rotary valves and with variable valve timing patented in 1849, invented by and named after the American engineer George Henry Corliss of Providence, Rhode Island.

W

WA Cornish engine is a type of steam engine developed in Cornwall, England, mainly for pumping water from a mine. It is a form of beam engine that uses steam at a higher pressure than the earlier engines designed by James Watt. The engines were also used for powering man engines to assist the underground miners' journeys to and from their working levels, for winching materials into and out of the mine, and for powering on-site ore stamping machinery.

W

WValve gear opens and closes valves in the correct order. In rotating engines valve timings can be driven by eccentrics or cranks, but in non-rotative beam engines these options are not available. In the Cornish engine valves are driven either manually or through ‘plug rods’ and tappets driven from the beam. This permits the insertions of delays at various points in the cycle, allowing a Cornish Engine to vary from one stroke in ten minutes, to ten or more strokes in one minute, but also leads to some less familiar components when compared with rotative engines.

W

WThe Creusot steam hammer is a giant steam hammer built in 1877 by Schneider and Co. in the French industrial town of Le Creusot. With the ability to deliver a blow of up to 100 tons, the Creusot hammer was the most powerful in the world until 1891, when the Bethlehem Iron Company of the United States purchased patent rights from Schneider and built a steam hammer of almost identical design but capable of delivering a 125-ton blow.

W

WHigh-speed steam engines were one of the final developments of the stationary steam engine. They ran at a high speed, of several hundred rpm, which was needed by tasks such as electricity generation.

W

WA house-built engine is a stationary steam engine that is built into an engine house, such that it uses the masonry of the engine house as an integral part of the support of the engine.

W

WStationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars, agricultural engines used for ploughing or threshing, marine engines, and the steam turbines used as the mechanism of power generation for most nuclear power plants.

W

WMusgrave's non-dead-centre engine was a stationary steam engine of unusual design, intended to solve the problem of stopping on dead centre. It was designed in 1887 to serve as a marine engine. It used a pair of linked cylinders to prevent the engine from stopping in a position where no turning force can be applied. At least one engine is known to survive.

W

WThe atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum which allowed the atmospheric pressure to push the piston into the cylinder. It was the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines. Hundreds were constructed throughout the 18th century.

W

WOld Bess is an early beam engine built by the partnership of Boulton and Watt. The engine was constructed in 1777 and worked until 1848.

W

WA portable engine is an engine, either a steam engine or an internal combustion engine, that sits in one place while operating, but is portable and thus can be easily moved from one work site to another. Mounted on wheels or skids, it is either towed to the work site or moves there via self-propulsion.

W

WA semi-portable engine is a form of stationary steam engine. They were built in a factory as a single unit including the boiler, so that they could be rapidly installed on site and brought into service.

W

WStationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars, agricultural engines used for ploughing or threshing, marine engines, and the steam turbines used as the mechanism of power generation for most nuclear power plants.

W

WA steeple compound engine is a form of tandem compound steam engine that is constructed as an inverted vertical engine. Because of their great height, they became known as "steeple" engines.

W

WA table engine is a variety of stationary steam engine where the cylinder is placed on top of a table-shaped base, the legs of which stand on the baseplate which locates the crankshaft bearings. The piston rod protrudes from the top of the cylinder and has fixed to it a cross-head which runs in slides attached to, and rising from, the cylinder top. Long return rods connect the crosshead to the crankshaft, on which is fixed the flywheel.

W

WThe Watt steam engine, alternatively known as the Boulton and Watt steam engine, was an early steam engine and was one of the driving forces of the Industrial Revolution. James Watt developed the design sporadically from 1763 to 1775 with support from Matthew Boulton. Watt's design saved so much more fuel compared with earlier designs that they were licensed based on the amount of fuel they would save. Watt never ceased developing the steam engine, introducing double-acting designs and various systems for deriving rotary power. Watt's design became synonymous with steam engines, and it was many years before significantly new designs began to replace the basic Watt design.

W

WThe Westonzoyland Pumping Station Museum of Steam Power and Land Drainage is a small industrial heritage museum dedicated to steam powered machinery at Westonzoyland in the English county of Somerset. It is a Grade II* listed building.

W

WThe Willans engine or central valve engine was a high-speed stationary steam engine used mainly for electricity generation around the start of the 20th century.