W

WFriction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:Dry friction is a force that opposes the relative lateral motion of two solid surfaces in contact. Dry friction is subdivided into static friction ("stiction") between non-moving surfaces, and kinetic friction between moving surfaces. With the exception of atomic or molecular friction, dry friction generally arises from the interaction of surface features, known as asperities Fluid friction describes the friction between layers of a viscous fluid that are moving relative to each other.Lubricated friction is a case of fluid friction where a lubricant fluid separates two solid surfaces.Skin friction is a component of drag, the force resisting the motion of a fluid across the surface of a body. Internal friction is the force resisting motion between the elements making up a solid material while it undergoes deformation.

W

WDissimilar friction stir welding (DFSW) is the application of friction stir welding (FSW), invented in The Welding Institute (TWI) in 1991, to join different base metals including aluminum, copper, steel, titanium, magnesium and other materials. It is based on solid state welding that means there is no melting. DFSW is based on a frictional heat generated by a simple tool in order to soften the materials and stir them together using both tool rotational and tool traverse movements. In the beginning, it is mainly used for joining of aluminum base metals due to existence of solidification defects in joining them by fusion welding methods such as porosity along with thick Intermetallic compounds. DFSW is taken into account as an efficient method to join dissimilar materials in the last decade. There are many advantages for DFSW in compare with other welding methods including low-cost, user-friendly, and easy operation procedure resulting in enormous usages of friction stir welding for dissimilar joints. Welding tool, base materials, backing plate (fixture), and a milling machine are required materials and equipment for DFSW. On the other hand, other welding methods, such as Shielded Metal Arc Welding (SMAW) typically need highly professional operator as well as quite expensive equipment.

W

WIn fluid flow, friction loss is the loss of pressure or “head” that occurs in pipe or duct flow due to the effect of the fluid's viscosity near the surface of the pipe or duct. In mechanical systems such as internal combustion engines, the term refers to the power lost in overcoming the friction between two moving surfaces, a different phenomenon.

W

WFriction stir spot welding is a pressure welding process that operates below the melting point of the workpieces. It is a variant of friction stir welding.

W

WNormal contact stiffness is a physical quantity related to the generalized force displacement behavior of rough surfaces in contact with a rigid body or a second similar rough surface.. Rough surfaces can be seen as consisting of large numbers asperities. As two solid bodies of the same material approach one another, asperities interact with one another and they transition from conditions of non-contact to homogeneous bulk type behaviour. The varying values of stiffness and true contact area that is exhibited at an interface during this transition is dependent on conditions of applied pressure and is of notable importance for the study of systems involving the physical interactions of multiple bodies including granular matter, electrode contacts, and thermal contacts, where the interface-localized structures govern overall system performance.

W

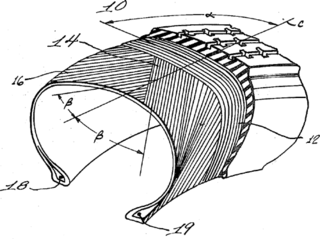

WA radial tire is a particular design of vehicular tire. In this design, the cord plies are arranged at 90 degrees to the direction of travel, or radially. Radial tire construction climbed to 100% market share in North America following Consumer Reports finding the superiority of the radial design in 1968, and were standard by 1976.

W

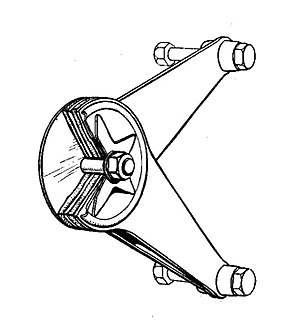

WFriction disk shock absorbers or André Hartford dampers were an early form of shock absorber or damper used for car suspension. They were commonly used in the 1930s but were considered obsolete post-war.

W

WSlipperiness is the degree of risk of slippage or falling when walking on a wet surface such as a pathway, boat deck or roadway. Road slipperiness is a major area of road safety, but various means have also been developed to measure walkway and deck slipperiness in order to develop health and safety standards. Energy loss over a measured distance of movement across a surface is called the "anti-slip" coefficient.

W

WTribo-Fatigue is a subdiscipline of mechanics, which studies wear-fatigue damage (WFD) in and the fracture of tribo-fatigue systems. The field was founded at the junction of tribology, and mechanics of fatigue damage and fracture in materials and structural elements.