W

WAn anti-tank mine is a type of land mine designed to damage or destroy vehicles including tanks and armored fighting vehicles.

W

WThe AT2 mine is a scatterable anti-tank mine developed by Dynamit Nobel. It can be scattered from artillery rockets or from mine laying systems, and was used by the British, German and Norwegian armed forces until the signing of the Ottawa Treaty.

W

WThe ATM-72 is a steel cased circular North Korean anti-tank mine. It is similar to the Russian TM-46, with a thick wire carrying handle and a filling plug. The mine uses a four pronged fuze, downward pressure on any of the levers will trigger the mine. The lever action of the mine makes it resistant to overpressure and blast.

W

WThe FFV 016 is a Swedish designed off-route mine designed for use against lightly armoured vehicles. The mine uses a Misznay Schardin effect warhead to produce a self-forging fragment that has an initial velocity of approximately 2,000 metres per second and can penetrate 60 mm of armour at 30 metres range. The mine's body is circular, with a dished front which is aimed using a simple built in sight along the expected route of the target.

W

WThe FFV 028 is a series of steel cased Swedish anti-tank mines that use electronic fuzes. The mines are circular, with a large Misznay Schardin effect warhead in the center of the mine, with the fuzing and sensor electronics located in the dead space above the main charge. The design of the mine dates from the 1970s and uses a magnetic influence sensor to detonate the mine, making it able to attack the full width of armoured vehicles.

W

WThe FMK-3 is a fibreglass cased Argentine anti-tank blast mine. It is produced by Direccion General de Fabricaciones Militares. The mine actually uses a FMK-1 anti-personnel mine as a fuze, the FMK-1 is modified with a pressure cap to increase the activation pressure. Argentina's stock of FMK-1 mines was modified in 2003 to prevent their use as anti-personnel mines, this involved welded an additional plastic pressure cap onto the mine. The mine has very little metal content, although an optional detection ring is provided with the FMK-1.

W

WThe Holzmine 42 was an anti-tank mine that was developed by Germany and used by the Wehrmacht during World War II.

W

WThe HPD-1, HPD-2 and HPD-3 are a series of French electrically fuzed anti-tank landmines that use Misznay Schardin effect warheads. The entire series of mines conform to the United States MIL-STD-331.

W

WKrakatoa is a modular explosive device used for explosive ordnance disposal (EOD) or demolitions developed by the British company Alford Technologies. The device is designed to fire a number of different projectiles, operates both in air and underwater, and can be used in a vertical or horizontal orientation.

W

WThe L.P.Z. mine or Leichte Panzermine was a circular, metal-cased German anti-tank mine produced during the Second World War. The mine was accepted into service in 1941, and were intended for use by Paratroops. Production of the mine ended in 1942 with only 31,700 mines produced. The mines were first used during Operation Merkur, the airborne invasion of Crete and were still in use at the end of the war.

W

WThe Shitotsubakurai lunge mine was a suicidal anti-tank weapon developed and used by the Empire of Japan during the Second World War. It used a HEAT type charge. This weapon was used by the CQC units of the Imperial Japanese Army. The weapon itself was a conical hollow charge anti-tank mine, placed inside a metallic container and attached to the end of a wooden stick. The weapon was officially adopted by the Japanese Army in 1945; in that year it caused its first victims in the Pacific Theater, where it commonly saw action against American armour. Later that year, some Japanese Imperial Army manuals of the weapon were discovered by US troops.

W

WThe M1, M1A1 and M4 are circular steel cased United States anti-tank blast mines with a distinctive cross shaped pressure spider. The mine was used during the Second World War and a copy produced in Argentina was used during the Falklands War. Another copy is produced in China. designated the No. 4 mine. Variants of the mine have also been deployed in Chad and Tunisia.

W

WThe M15 mine is a large circular United States anti-tank blast mine, first deployed during the Korean War. Essentially, it is a larger version of the M6A2 anti-tank mine, which it replaced. Although the M15 has been superseded by the M19 mine, the U.S. retains large stocks of M15s because they are still regarded as reliable and effective weapons. When used against main battle tanks the M15 is primarily a "track-breaker" which creates mobility kills, but has a comparatively small likelihood of causing crew fatalities. However, when used against lighter vehicles such as APCs or unarmored vehicles such as trucks the damage inflicted is much more severe.

W

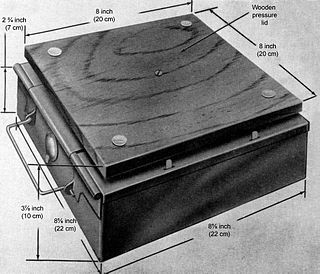

WThe M19 is a large square plastic cased United States anti-tank blast mine. Intended to replace the M15 mine, the design dates from the mid-1960s and contains only two metal components: the copper detonator capsule and a stainless steel firing pin which weighs 2.86 grams. It is a minimum metal mine, which makes it very difficult to detect after it has been emplaced. This mine is produced under licence in Chile, South Korea and Turkey. A copy is produced in Iran. It is found in Afghanistan, Angola, Chad, Chile, Cyprus, Iran, Iraq, Jordan, South Korea, Lebanon, the Western Sahara, and Zambia.

W

WThe M1935 is a French heavy anti-tank mine. It consists of a large heavy steel base plate with a hinged thin steel lid. Inside the lid it has a rectangular steel container, which holds the explosive charge. The mines are laid at a minimum interval of six feet.

W

WThe M1936 (Mle1936) is a French light anti-tank mine used during the Second World War. The mine was captured in large numbers by the German army after the Fall of France, and was later used in the Atlantikwall, North Africa and Italy. The mine consists of a base plate on top of which is a rectangular steel box containing an explosive charge. On top of the container are two M1935 or M1936 pressure fuzes. A pressure cover is fixed on top of the container by wires attached at either end of the container. Two pressure bars are welded to the inside of the pressure cover, each one is directly over a fuze—however, each bar has a recess preventing it from pressing on the pressure fuze, until a safety bar is inserted. The safety bar covers the recesses allowing the pressure cover to bear down directly on the pressure fuzes.

W

WThe MN-111 is a Polish air-dropped anti-tank landmine. The mine is designed for use on soft ground. The mine is cylindrical with six spring-loaded fins attached to one end of the mine, with the cylinder drawn to a point at the opposite end which is topped with a small wind vane. The mine is stored with the fins wrapped round the outside of the mine. Once the mine is dropped from the aircraft the fins spring outward, acting as a drag parachute, slowing the rate of descent to a peak speed of about 60 meters per second. As the mine drops the wind vane spins, generating the power used to arm the mine.

W

WThe MN-121 is a Polish scatterable anti-tank mine, externally similar to the German AT-2 mine. The mine is cylindrical with ten wire legs which fold outward to keep the mine upright. The mine uses a magnetic influence fuze, which triggers the mine when a vehicle passes over it. The mine also has an anti-handling device which triggers the mine if it is moved. The mine's warhead is a shaped charge design containing approximately 700 grams of RDX. The manufacturer claims that it is capable of penetrating 60 millimeters of armour at an offset of half a meter.

W

WThe MPB is a Polish off-route anti-tank mine. It was developed by BELMA with its partner Military Institute of Engineer Technology. The MPB consists of a metal cylinder filled with explosives, mounted horizontally in an adjustable frame. The mine is intended to be hidden from direct view of the intended target, off to the side of a probable vehicle route, usually a road, to attack the weaker armour on the sides and rear of a vehicle. The mine can be triggered by either a contact fuze or an influence fuze based on infrared and acoustic sensors, and is also fitted with an anti-handling device. When used with the passive infrared fuze, an acoustic sensor detects approaching vehicles and activates the infrared sensor, which triggers the mine at an optimal moment as the target passes. The mine can be programmed to self-destruct after either 1, 10 or 30 days have passed.

W

WThe Panzer-Stabmine 43 was a German anti-tank mine, together with the Hohl-Sprung mine 4672 it was the first mine to combine a shaped charge warhead with a tilt-rod fuze. The mine was developed during the Second World War. The mine consisted of a wine glass shaped metal main body mounted on a wooden post, with a tilt rod holding arm projecting to one side. It used a 125 mm diameter warhead with 1.6 kg of explosive, and a combination pressure/tilt fuze.

W

WThe PARM 1 (DM-12) and PARM 2 are German off-route mines that fire small fin stabilized rockets.

W

WThe Riegel mine 43 or is a German steel cased anti-tank bar mine used during the Second World War. The mine is a long thin rectangle. It consists of a lower and upper metal tray, and an internal metal-cased explosive block. It uses two ZZ42 fuzes inserted into either end of the internal block, although it can be used with an additional pressure fuze on the top. The mine is similar to the Italian B-2 mine. A variant, the Riegel mine 44 was also produced with a different fuze. Approximately 3,051,400 were produced between 1943 and 1945.

W

WThe Shielder minelaying system was used by the British Army to create anti-tank barriers quickly. The system was based on the American Alliant Techsystems Volcano mine system. It was ordered in 1995 and first deployed in 1999. The system consists of up to 40 dispensers, each containing 6 mines, mounted on the flat bed version of the Alvis Stormer tracked armoured fighting vehicle. The dispensers can launch mines to the sides and rear of the vehicle as it proceeds. Each mine has a programmable life, after which they self-destruct. A dispenser control unit provides fire signals, testing and arming of the self-destruct mechanism.

W

WThe T-IV was a Soviet anti-tank mine developed before and used during the Second World War. The mine has a metal case with a wooden pressure plate attached to the top of the mine. It is similar in configuration to the later TM-38.

W

WThe Teller mine was a German-made antitank mine common in World War II. With explosives sealed inside a sheet metal casing and fitted with a pressure-actuated fuze, Teller mines had a built-in carrying handle on the side. As the name suggests the mines were plate-shaped.

W

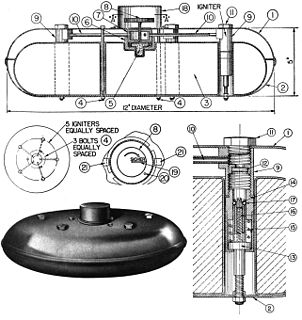

WThe Tellermine 29 is a round, metal-cased German anti-tank blast landmine. It first entered service in 1929, and the initial German defence plan was to purchase 6,000 a year, but in January 1931 it was decided to speed up the purchase process, and 61,418 were ordered. By 1937, with the introduction of the Tellermine 35, it was being used for training, and the majority were sent to warehouses.

W

WThe Tellermine 35 (T.Mi.35) was a German metal-cased anti-tank mine used extensively during the Second World War. The mine's case is made of sheet steel, and has a slightly convex pressure plate on the top surface with a central fuze well. Two secondary fuze wells are located on the side and bottom of the mine for anti-handling devices.

W

WThe Tellermine 42 (T.Mi.42) was a German metal-cased anti-tank blast mine used during the Second World War. The mine was a development of the Tellermine 35 with improved resistance to blast. It was followed by the simplified Tellermine 43.

W

WThe Tellermine 43 was a German circular steel cased anti-tank blast mine used during the Second World War. It was a simplified version of the Tellermine 42, which enabled simpler production techniques. Between March 1943 and the end of World War II, over 3.6 million Tellermine 43s were produced by Germany. Copies of the mine were produced by several countries including Denmark (M/47), France and Yugoslavia (TMM-1).

W

WThe TM-35 was a rectangular, metal-cased Soviet anti-tank mine used during the Second World War. The mine has a metal case, which is rectangular with a carrying handle on one side and a large raised pressure plate in the centre. Sufficient pressure on the central pressure plate presses down on one end of an internal see-saw like lever, which removes the retaining pin from an MUV fuze, releasing the striker, triggering the mine.

W

WThe TM-38 was a rectangular, metal-cased Soviet anti-tank mine used during the Second World War. The mine had a large raised rectangular central pressure plate with four reinforcing creases. When enough pressure was applied to the plate it collapses pressing down on a bolt connected to an internal lever. The lever is pulls a retaining pin from the MUV fuze, which releases the striker, which impacts the MD-2 detonator.

W

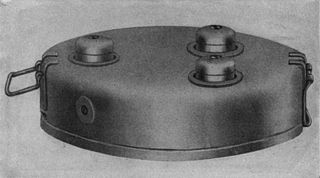

WThe TM-46 mine is a large, circular, metal-cased Soviet anti-tank mine. It uses either a pressure fuze or tilt-rod, which is screwed into the top. Anti-tank mines with this type of fuze were capable of inflicting much more damage to armored vehicles. The TMN-46 is a variant of the mine fitted with a secondary fuze well on the bottom which is slightly off-set from the centre of the mine. This secondary fuze well can be fitted with a pull-fuze which functions as an anti-handling device. The mine was used by the North Vietnamese forces during the Vietnam War, and is found in many countries in Africa, the Middle East and South East Asia.

W

WThe TM-57 mine is a large, circular Soviet metal-cased blast anti-tank mine. It can either be triggered by a pressure or a tilt-rod fuze. A development of the TM-46 mine, it is found in Africa, the Middle East, and South East Asia.

W

WTM-62 is the designation for a series of Soviet anti-tank blast mines. The mines have a central fuze and typically have a 7.5 kilograms (17 lb) explosive charge, however they vary greatly in detail. The mines can be laid manually or automatically from a mine laying machine including the PMR-1, PMR-2 wheeled towed mine layers, the GMZ tracked mine laying vehicle and the VMR-2 helicopter mine laying system.

W

WThe TM-72 is a Soviet cylindrical metal-cased anti-tank mine. It is normally used with the MVN-72 or MVN-80 magnetic influence fuzes, which give it a full width attack capability. It uses a 2.5 kg shaped charge warhead capable of penetrating approximately 100 millimeters of armor at a standoff distance of between 0.25 and 0.5 meters. It is compatible with the fuzes used with the TM-62 series of mines.

W

WThe TMA-1 and TMA-1A are circular, plastic cased Yugoslavian minimum metal anti-tank blast mine. The mine consists of an upper plastic pressure plate, and the lower body containing the main charge. The pressure plate has eight triangular raised sectors, and a central fuze cap. The pressure plate is held in place by four plastic pins, which when suffient pressure is applied, shear allowing the pressure plate to collapse onto the mine body, triggering the UANU-1 fuze. A secondary fuze well is provided in the base of the mine, allowing the use of anti-handling devices. The mine is found in Bosnia, Croatia and Kosovo.

W

WThe TMA-2 is a rectangular plastic cased Yugoslavian minimum metal anti-tank blast mine. It is very similar in appearance and size to the PT-56, which it replaced. The mine consists of two sections, an upper ribbed pressure plate with two large circular fuze caps, and a lower base section containing the main charge and two primary fuze wells containing UANU-1 fuzes. A secondary fuze well is provided in the base of the mine for an anti-handling device.

W

WThe TMA-3 is a circular Yugoslavian minimum metal anti-tank blast mine. It is very similar in appearance to the TMA-4. The mine consists of a cast circular block of explosive cased in resin reinforced fabric. The top of the mine has three fuze wells which each take a UTMA-3 fuze, and a fourth secondary fuze well is provided in the base of the mine to fit an anti-handling device. The fuze wells may also accept a number of other fuzes, including the UPROM-1, and other fuzes, potentially allowing tripwire activation. The small pressure plate area of the UTMA-3 fuzes gives the mine good resistance to minefield clearance techniques which used blast overpressure techniques i.e. explosive charges.

W

WThe TMA-4 is a circular plastic cased Yugoslavian minimum metal anti-tank blast mine. It is a modernized version of the TMA-3. The mine is basically a cast block of TNT with three fuze wells cut into it, encased in plastic. Three black plastic UTMA-4 fuzes are installed into the top surface of the mine. A thin rope carry handle is also provided. The small pressure plate area of the fuzes make the mine resistant to overpressure from explosive demining techniques. Additionally the low metal content of the mine make it very difficult to detect. Although no secondary fuze well is provided, it is possible that the mine could be fitted with improvised anti-handling devices.

W

WThe TMRP-6 is a former Yugoslavian anti tank EFP mine.

W

WThe Topfmines were a series of German circular minimum metal anti-tank blast mines that entered service with the German army in 1944, during the Second World War.

W

WThe TQ-Mi is an obsolete circular Czechoslovakian anti-tank blast mine. The mines body is made of cardboard impregnated with asphalt. A central pressure cap is made of glass, which sits on top of a chemical fuze, which is crushed open onto the booster charge. The booster charge is embedded in the TNT main charge, above which are a number of scrap metal fragments, giving a secondary anti-personnel effect.

W

WThe Type 72 is a Chinese metal-cased circular anti-tank blast mine, it is similar to the Russian TM-46 mine, a plastic cased version of the mine is also produced, the Type 72 non-metallic anti-tank mine. The mine has a central plastic cased blast resistant fuze.

W

WThe Type 99 (Hako-Baku-Rai) mine was a Japanese anti-tank weapon used during the Second World War. It entered service in 1939. Four magnets were attached to the casing made of hemp cloth, along with an external fuze. The fuze had a time delay, which enabled it to be used as an anti-tank hand grenade, or a demolition charge. Once the safety pin was removed, it was armed, striking the fuze ignited a powder delay train. The mine detonated after a five to ten seconds delay, giving enough time for it to be thrown.

W

WThe VS-1.6 is an Italian circular plastic-cased scatterable anti-tank blast mine. It has very few metal components and is resistant to overpressure and shock. The mine can also be deployed conventionally and from helicopters. It was produced by Valsella Meccanotecnica, but production has ceased.

W

WThe YaM-5 was a Soviet anti-tank blast mine with a wood case. Various wood was used. The mine consists of a rectangular wooden box with a hinged lid that overlaps the front of the mine. A slot in the hinged lid's side through which an MUV pull fuse is placed. A wooden pressure bar is sometimes used on the edge of the lid above the slot. A nail is placed horizontally through the loop of the MUV fuse's striker retaining pin and two loops on the bottom of the lid's slot.