W

WA heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

W

WAn intercooler is a mechanical device used to cool a gas after compression. Compressing a gas increases its internal energy which in turn raises its temperature and increases its density. An intercooler typically takes the form of a heat exchanger that removes waste heat in a gas compressor. Intercoolers have a variety of applications, and can be found, for instance, in air compressors, air conditioners, refrigeration, gas turbines, and automotive engines. They are widely known as an air-to-air or air-to-liquid cooler for forced induction internal combustion engines, used to improve volumetric efficiency. This is accomplished by increasing intake air density through nearly constant pressure cooling.

W

WBaffles are flow-directing or obstructing vanes or panels used in some industrial process vessels (tanks), such as shell and tube heat exchangers, chemical reactors, and static mixers. Baffles are an integral part of the shell and tube heat exchanger design. A baffle is designed to support tube bundles and direct the flow of fluids for maximum efficiency. Baffle design and tolerances for heat exchangers are discussed in the standards of the Tubular Exchanger Manufacturers Association (TEMA).

W

WIn systems involving heat transfer, a condenser is a device or unit used to condense a gaseous substance into a liquid state through cooling. In so doing, the latent heat is released by the substance and transferred to the surrounding environment. Condensers are used for efficient heat rejection in many industrial systems. Condensers can be made according to numerous designs, and come in many sizes ranging from rather small (hand-held) to very large. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air.

W

WA downhole heat exchanger, (DHE) also called a borehole heat exchanger, (BHE) is a heat exchanger installed inside a borehole. It is used to capture or dissipate heat to or from the ground. DHT's are used for geothermal heating, sometimes with the help of a geothermal heat pump.

W

WA tubular grate heater is any grate or heat exchanger for a fireplace designed from metal tubing. Through the tubing is circulated home air that becomes heated by the fire. The air is then vented back into the room and home. It is a heat recovery device that improves the efficiency and ability of a fireplace to get the heat from the fire out and into the home. From simple to ornate, they can contribute significantly to the overall comfort of a room and potentially to a whole house. This in turn will reduce the amount of firewood needed to achieve the same comfort level, potentially reducing heating costs and expenses. Heaters increase the efficiency of a fireplace and hence the amount of heat that makes it from the fireplace out into the home. They work by having naturally convected and forced air funneled into the metal heat exchanger tubing that is then heated by the coals and/or fire. They draw in cold air from the floor and blow heated air back out into your home. This adds an element of conductive and convective heating to the radiant heat typical of a basic fireplace. Grate heaters have been called many things: heatilator, hearth heater, fireplace blower, fireplace grate heater, Fireplace Furnace, tubular grate heater, etc.

W

WA heat sink is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, thereby allowing regulation of the device's temperature. In computers, heat sinks are used to cool CPUs, GPUs, and some chipsets and RAM modules. Heat sinks are used with high-power semiconductor devices such as power transistors and optoelectronics such as lasers and light emitting diodes (LEDs), where the heat dissipation ability of the component itself is insufficient to moderate its temperature.

W

WA heater core is a radiator-like device used in heating the cabin of a vehicle. Hot coolant from the vehicle's engine is passed through a winding tube of the core, a heat exchanger between coolant and cabin air. Fins attached to the core tubes serve to increase surface area for heat transfer to air that is forced past them by a fan, thereby heating the passenger compartment.

W

WAn intercooler is a mechanical device used to cool a gas after compression. Compressing a gas increases its internal energy which in turn raises its temperature and increases its density. An intercooler typically takes the form of a heat exchanger that removes waste heat in a gas compressor. Intercoolers have a variety of applications, and can be found, for instance, in air compressors, air conditioners, refrigeration, gas turbines, and automotive engines. They are widely known as an air-to-air or air-to-liquid cooler for forced induction internal combustion engines, used to improve volumetric efficiency. This is accomplished by increasing intake air density through nearly constant pressure cooling.

W

WIn chemical engineering, a jacketed vessel is a container that is designed for controlling temperature of its contents, by using a cooling or heating "jacket" around the vessel through which a cooling or heating fluid is circulated.

W

WMarine heat exchangers are no different than non-marine heat exchangers except for the simple fact that they are found aboard ships. Heat exchangers can be used for a wide variety of uses. As the name implies, these can be used for heating as well as cooling. The two primary types of marine heat exchangers used aboard vessels in the maritime industry are plate, and shell and tube. Maintenance for heat exchangers prevents fouling and galvanic corrosion from dissimilar metals.

W

WPinch analysis is a methodology for minimising energy consumption of chemical processes by calculating thermodynamically feasible energy targets and achieving them by optimising heat recovery systems, energy supply methods and process operating conditions. It is also known as process integration, heat integration, energy integration or pinch technology.

W

WRadiators are heat exchangers used for cooling internal combustion engines, mainly in automobiles but also in piston-engined aircraft, railway locomotives, motorcycles, stationary generating plant or any similar use of such an engine.

W

WRadiators and convectors are heat exchangers designed to transfer thermal energy from one medium to another for the purpose of space heating.

W

WA recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat. Generally, they are used to extract heat from the exhaust and use it to preheat air entering the combustion system. In this way they use waste energy to heat the air, offsetting some of the fuel, and thereby improves the energy efficiency of the system as a whole.

W

WA sectional cooler is a rotary drum cooler used for continuous processes in chemical engineering.

W

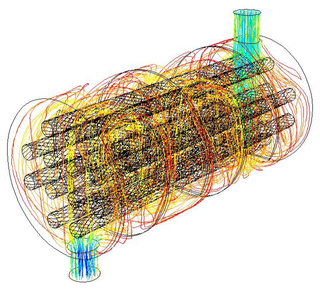

WA shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc.

W

WA surface condenser is a commonly used term for a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure as a water-cooled surface condenser.

W

WA thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of an air-handling system or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel.

W

WThe Tubular Exchanger Manufacturers Association is an association of fabricators of shell and tube type heat exchangers. TEMA has established and maintains a set of construction standards for heat exchangers, known as the TEMA Standard.. TEMA also produces software for evaluation of flow-induced vibration and of flexible shell elements. TEMA was founded in 1939, and is based in Tarrytown, New York. The association meets regularly to revise and update the standards, respond to inquiries, and discuss topics related to the industry.

W

WA waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling.

W

WA water block is the watercooling equivalent of a heatsink. It is a type of plate heat exchanger and can be used on many different computer components, including the central processing unit (CPU), GPU, PPU, and Northbridge chipset on the motherboard. It consists of at least two main parts; the "base",which is the area that makes contact with the device being cooled and is usually manufactured from metals with high thermal conductivity such as aluminum or copper. The second part, the "top" ensures the water is contained safely inside the water block and has connections that allow hosing to connect it with the water cooling loop. The top can be made of the same metal as the base, transparent Perspex, Delrin, Nylon, or HDPE. Most newer high-end water blocks also contain mid-plates which serve to add jet tubes, nozzles, and other flow altering devices.