W

WA kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing—to calcinate ores, to calcinate limestone to lime for cement, and to transform many other materials.

W

WThe anagama kiln is an ancient type of pottery kiln brought to Japan from China via Korea in the 5th century. It is a version of the climbing dragon kiln of south China, whose further development was also copied, for example in breaking up the firing space into a series of chambers in the noborigama kiln.

W

W3D Model of Coal Kilns created by Chris Baker

W

WA bottle kiln, or bottle oven, is a type of kiln. The word 'bottle' refers to the shape of the structure and not to the kiln's products, which are usually pottery, not glass.

W

WA bottle kiln, or bottle oven, is a type of kiln. The word 'bottle' refers to the shape of the structure and not to the kiln's products, which are usually pottery, not glass.

W

WA brick clamp is a traditional method of baking bricks, done by stacking unbaked bricks with fuel under or among them, then igniting the fuel. The clamp is considered a type of kiln. If the clamp is insulated by packing earth or mud around it, it becomes a scove kiln.

W

WCatawba Valley Pottery describes alkaline glazed stoneware made in the Catawba River Valley of Western North Carolina from the early 19th century, as well as certain contemporary pottery made in the region utilizing traditional methods and forms.

W

WCharcoal is a lightweight black carbon residue produced by strongly heating wood so as to drive off all water and other volatile constituents. In the traditional version of this pyrolysis process, called charcoal burning, the heat is supplied by burning part of the starting material itself, with a limited supply of oxygen. Charcoal can also be produced by heating the material in a closed retort.

W

WThe Charcoal Kilns near Eureka, Utah were listed on the National Register of Historic Places in 1979. The listing included two charcoal kilns that each are about six feet in diameter and four feet deep, built out of stone. They are believed to have been built or used to support the Wyoming Smelter in 1871.

W

WThe Continental Clay Brick Plant in Martinsburg, West Virginia includes a number of beehive brick kilns. Originally a coal-fired brickworks, it was later converted to natural gas. The kilns are now largely disused, except for a few used to dry sand.

W

WA dragon kiln or "climbing kiln", is a traditional Chinese form of kiln, used for Chinese ceramics, especially in southern China. It is long and thin, and relies on having a fairly steep slope, typically between 10° and 16°, up which the kiln runs. The kiln could achieve the very high temperatures, sometimes as high as 1400°C, necessary for high-fired wares including stoneware and porcelain, which long challenged European potters, and some examples were very large, up to 60 metres long, allowing up to 25,000 pieces to be fired at a time. By the early 12th century CE they might be over 135 metres long, allowing still larger quantities to be fired; more than 100,000 have been claimed.

W

WRotary drum, also named rotary dryer, is a machine for drying process, which people call rotary drying. It’s a special kiln that usually co-works with burning system, like coal burner or oil burner. The heat goes through its inner cylinder, dehydrating the material inside. The materials can be added in and withdrawn during the drying process, so it can work continuously.

W

WThe Five Great Kilns, also known as Five Famous Kilns, is a generic term for ceramic kilns or wares which produced Chinese ceramics during the Song dynasty (960–1279) that were later held in particularly high esteem. The group were only so called by much later writers, and of the five, only two seem to have produced wares directly ordered by the Imperial court, though all can be of very high quality. All were imitated later, often with considerable success.

W

WThe Hoffmann kiln is a series of batch process kilns. Hoffmann kilns are the most common kiln used in production of bricks and some other ceramic products. Patented by German Friedrich Hoffmann for brickmaking in 1858, it was later used for lime-burning, and was known as the Hoffmann continuous kiln.

W

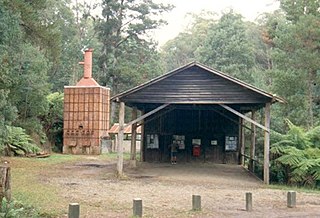

WKurth Kiln was established by the Forests Commission Victoria in 1941 on a site about 7 km north of Gembrook on the Tomahawk Creek.

W

WA lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide). The chemical equation for this reaction isCaCO3 + heat → CaO + CO2

W

WA limepit is either a place where limestone is quarried, or a man-made pit used to burn lime stones in the same way that modern-day kilns and furnaces constructed of brick are now used above ground for the calcination of limestone and by which quicklime is produced, an essential component in waterproofing and in wall plastering.

W

WThe mantou kiln or horseshoe-shaped kiln was the most common type of pottery kiln in north China, in historical periods when the dragon kiln dominated south China; both seem to have emerged in the Warring States period of approximately 475 to 221 BC. It is named after the Chinese mantou bun or roll, whose shape it resembles; the ground plan resembles a horseshoe. The kilns are roughly round, with a low dome covering the central firing area, and are generally only 2 to 3 metres across inside. However it is capable of reaching very high temperatures, up to about 1370°C. There is a door or bricked-up opening at the front for loading and unloading, and one or two short chimneys at the rear.

W

WThe Piedmont Charcoal Kilns in Piedmont, Wyoming, are a remnant of a once-extensive charcoal-making industry in southwestern Wyoming. The kilns were built by Moses Byrne around 1869 near the Piedmont Station along the Union Pacific Railroad. The three surviving beehive-shaped kilns were built of local sandstone about 30 feet (9.1 m) in circumference and about 30 feet (9.1 m) high, with 24-inch-thick (61 cm) walls. A granite marker reads:Charcoal Kilns were built by Moses Byrne, 1869, to supply the pioneer smelters in the Utah Valley.

W

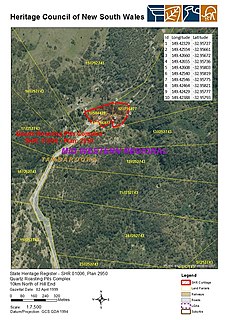

WQuartz Roasting Pits Complex is a heritage-listed quartz roasting kiln located 10km north of Hill End, Mid-Western Regional Council, New South Wales, Australia. It was built from 1854 to 1855. It is also known as Cornish Roasting Pits. The property is owned by the New South Wales Office of Environment and Heritage. It was added to the New South Wales State Heritage Register on 2 April 1999.

W

WA rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include:Cement Lime Refractories Metakaolin Titanium dioxide Alumina Vermiculite Iron ore pellets

W

WThe Soldier Creek Kilns near Stockton, Utah date from about 1873, the time of their construction, and were in use up until about 1899. Also known as the Waterman Coking Ovens, they were listed on the National Register of Historic Places (NRHP) in 1980. The listing included 14 contributing structures over 30 acres (12 ha).

W

WTar is a dark brown or black viscous liquid of hydrocarbons and free carbon, obtained from a wide variety of organic materials through destructive distillation. Tar can be produced from coal, wood, petroleum, or peat.

W

WA tube furnace is an electric heating device used to conduct syntheses and purifications of inorganic compounds and occasionally in organic synthesis. One possible design consists of a cylindrical cavity surrounded by heating coils that are embedded in a thermally insulating matrix. Temperature can be controlled via feedback from a thermocouple. More elaborate tube furnaces have two heating zones useful for transport experiments. Some digital temperature controllers provide an RS-232 interface, and permit the operator to program segments for uses like ramping, soaking, sintering, and more. Advanced materials in the heating elements, such as molybdenum disilicide offered in certain models can now produce working temperatures up to 1800 °C. This facilitates more sophisticated applications. Common material for the reaction tubes include alumina, Pyrex, and fused quartz, or in the case of corrosive materials molybdenum or tungsten tubes can be used.

W

WThe Tybo Charcoal Kilns are a pair of charcoal kilns located 4 miles (6.4 km) north of Tybo, Nevada. Both kilns are 30 feet (9.1 m) tall and 25 feet (7.6 m) in diameter and were built from rocks and mud. The kilns each have three openings: a top opening, a door at ground level, and a rear window with a ramp for wood wagons. The kilns were among 15 built in 1874 for the Tybo Consolidated Company. The company, which mined the region's silver, used charcoal to fuel its smelting furnace. To acquire its fuel, it imported wood from nearby hills, which it then converted to charcoal in the kilns.

W

WThe Walker Charcoal Kiln is a structure in the Prescott National Forest near the town of Walker, Arizona and situated in the vicinity of the abandoned Poland Junction Mine near the summit of Renegade Hill. It is listed on the National Register of Historic Places. A sign posted near the kiln reads, "This kiln was constructed around 1880 by Jake and Joe Carmichael to convert oak wood into charcoal for use at nearby smelters. The surrounding forest was cut so heavily for charcoal and mine props in the late 1800s that it is just now becoming productive again." Locally, the kiln is referred to as "the Beehive".

W

WJ. H. Wilkerson & Son Brickworks was a historic abandoned brickworks and national historic district located at Milford, Kent County, Delaware. The district includes the sites of three contributing buildings and one contributing site at the brickworks that operated from 1912 to 1957. The sheds, machinery, kiln, and other structures which housed the machinery remain standing, others have deteriorated or collapsed. last standing werere the storage shed, the shed over the brick-making machine, and one of the drying sheds. All of the machinery was in place as were other pieces of equipment used in the brick-making process. The walls of the kiln remain standing, just as they would have been left after the fired bricks are removed.