W

WA mechanical linkage is an assembly of bodies connected to manage forces and movement. The movement of a body, or link, is studied using geometry so the link is considered to be rigid. The connections between links are modeled as providing ideal movement, pure rotation or sliding for example, and are called joints. A linkage modeled as a network of rigid links and ideal joints is called a kinematic chain.

W

WIn mechanical engineering, an Assur group is a kinematic chain with zero degree of mobility, which added or subtracted from a mechanism do not alter its original number of degrees of freedom. They have been first described by the Russian engineer Leonid Assur (1878–1920) in 1914.,

W

WIn geometry, a Bricard octahedron is a member of a family of flexible polyhedra constructed by Raoul Bricard in 1897. That is, it is possible for the overall shape of this polyhedron to change in a continuous motion, without any changes to the lengths of its edges nor to the shapes of its faces. These octahedra were the first flexible polyhedra to be discovered.

W

WThe Chebyshev linkage is a mechanical linkage that converts rotational motion to approximate straight-line motion.

W

WThe Chebyshev's Lambda Mechanism is a four-bar mechanism that converts rotational motion to approximate straight-line motion with approximate constant velocity. The precise design trades off straightness, lack of acceleration, and the proportion of the driving rotation that is spent in the linear portion of the full curve.

W

WIn kinematics, cognate linkages are linkages that ensure the same input-output relationship or coupler curve geometry, while being dimensionally dissimilar. In case of four-bar linkage coupler cognates, the Roberts–Chebyschev Theorem, after Samuel Roberts and Pafnuty Chebyshev, states that each coupler curve can be generated by three different four-bar linkages. These four-bar linkages can be constructed using similar triangles and parallelograms, and the Cayley diagram.

W

WA concealed hinge drilling jig is a type of support jig, designed for drilling 3 cm holes to fit concealed hinges into modern wardrobe doors. As many of the complementary tools used in woodworking, it uses an electric hand-drill for its operation, making a Forstner bit to turn.

W

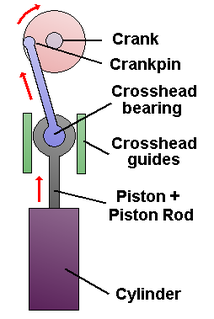

WA connecting rod, also called a con rod, is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston, and rotate at both ends.

W

WA crank is an arm attached at a right angle to a rotating shaft by which circular motion is imparted to or received from the shaft. When combined with a connecting rod, it can be used to convert circular motion into reciprocating motion, or vice versa. The arm may be a bent portion of the shaft, or a separate arm or disk attached to it. Attached to the end of the crank by a pivot is a rod, usually called a connecting rod (conrod).

W

WA four-bar linkage, also called a four-bar, is the simplest movable closed-chain linkage. It consists of four bodies, called bars or links, connected in a loop by four joints. Generally, the joints are configured so the links move in parallel planes, and the assembly is called a planar four-bar linkage. Spherical and spatial four-bar linkages also exist and are used in practice.

W

WA crankshaft is a shaft driven by a crank mechanism, consisting of a series of cranks and crankpins to which the connecting rods of an engine are attached. It is a mechanical part able to perform a conversion between reciprocating motion and rotational motion. In a reciprocating engine, it translates reciprocating motion of the piston into rotational motion, whereas in a reciprocating compressor, it converts the rotational motion into reciprocating motion. In order to do the conversion between two motions, the crankshaft has "crank throws" or "crankpins", additional bearing surfaces whose axis is offset from that of the crank, to which the "big ends" of the connecting rods from each cylinder attach.

W

WA crosshead is a mechanism used as part of the slider-crank linkages of long reciprocating engines and reciprocating compressors to eliminate sideways pressure on the piston. Also, the crosshead enables the connecting rod to freely move outside the cylinder. Because of the very small bore-to-stroke ratio on such engines, the connecting rod would hit the cylinder walls and block the engine from rotating if the piston was attached directly to the connecting rod like on trunk engines. Therefore, the longitudinal dimension of the crosshead must be matched to the stroke of the engine.

W

WA deployable structure is a structure that can change shape so as to significantly change its size.

W

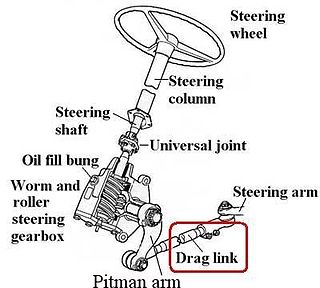

WA drag link converts rotary motion from a crank arm, to a second bellcrank, usually in an automotive steering system.

W

WA dwell mechanism is an intermittent motion mechanism that alternates forward and return motion with holding position(s).

W

WAn eight-bar linkage is a one degree-of-freedom mechanism that is constructed from eight links and 10 joints. These linkages are rare compared to four-bar and six-bar linkages, but two well-known examples are the Peaucellier linkage and the linkage designed by Theo Jansen for his walking machines.

W

WA four-bar linkage, also called a four-bar, is the simplest movable closed-chain linkage. It consists of four bodies, called bars or links, connected in a loop by four joints. Generally, the joints are configured so the links move in parallel planes, and the assembly is called a planar four-bar linkage. Spherical and spatial four-bar linkages also exist and are used in practice.

W

WA geared continuous hinge is a type of continuous hinge used mostly on doors in high-traffic entrances and features gear teeth that mesh together under a cap that runs the length of the hinge. The hinges use a number of fasteners to attach the door to the frame from top to bottom to distribute a door’s weight more evenly along the frame to stop doors from sagging. They are often used in schools, hospitals, hotels, offices, airports, stadiums, storefronts and many other commercial and industrial buildings.

W

WHart's inversor is one of two mechanisms that provides a perfect straight line motion without sliding guides. They were invented and published by Harry Hart in 1874–5.

W

WA hinge is a mechanical bearing that connects two solid objects, typically allowing only a limited angle of rotation between them. A hinge is useful in mounting glass panels in shower or bathtub closets. Two objects connected by an ideal hinge rotate relative to each other about a fixed axis of rotation: all other translations or rotations being prevented, and thus a hinge has one degree of freedom. Hinges may be made of flexible material or of moving components. In biology, many joints function as hinges like the elbow joint.

W

WA Hoberman sphere is an isokinetic structure patented by Chuck Hoberman that resembles a geodesic dome, but is capable of folding down to a fraction of its normal size by the scissor-like action of its joints. Colorful plastic versions have become popular as children's toys: several toy sizes exist, with the original design capable of expanding from 5.9 inches (15 cm) in diameter to 30 inches (76 cm).

W

WThe Hoeckens linkage is a four-bar mechanism that converts rotational motion to approximate straight-line motion. It is named after Karl Hoecken (1874−1962).

W

WJansen's linkage is a planar leg mechanism designed by the kinetic sculptor Theo Jansen to generate a smooth walking motion. Jansen has used his mechanism in a variety of kinetic sculptures which are known as Strandbeesten. Jansen's linkage bears artistic as well as mechanical merit for its simulation of organic walking motion using a simple rotary input. These leg mechanisms have applications in mobile robotics and in gait analysis.

W

WThe Klann linkage is a planar mechanism designed to simulate the gait of legged animal and function as a wheel replacement, a leg mechanism. The linkage consists of the frame, a crank, two grounded rockers, and two couplers all connected by pivot joints. It was developed by Joe Klann in 1994 as an expansion of Burmester curves which are used to develop four-bar double-rocker linkages such as harbor crane booms. It is categorized as a modified Stephenson type III kinematic chain.

W

WA leg mechanism is a mechanical system designed to provide a propulsive force by intermittent frictional contact with the ground. This is in contrast with wheels or continuous tracks which are intended to maintain continuous frictional contact with the ground. Mechanical legs are linkages that can have one or more actuators, and can perform simple planar or complex motion. Compared to a wheel, a leg mechanism is potentially better fitted to uneven terrain, as it can step over obstacles.

W

WMetal expansion joints are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that depend on the application. They are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints. Expansion joints have usage in various sectors, like energy productions, paper industry, chemical industry, water treatment, oil and gas. Everywhere where exist pipelines and occurs thermal movements or vibration, then expansion joints can be used.

W

WAn overconstrained mechanism is a linkage that has more degrees of freedom than is predicted by the mobility formula. The mobility formula evaluates the degree of freedom of a system of rigid bodies that results when constraints are imposed in the form of joints between the links.

W

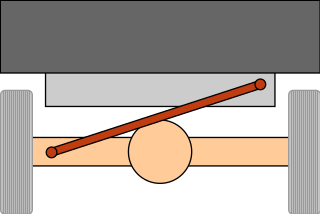

WA Panhard rod is a suspension link that provides lateral location of the axle. Originally invented by the Panhard automobile company of France in the early twentieth century, this device has been widely used ever since.

W

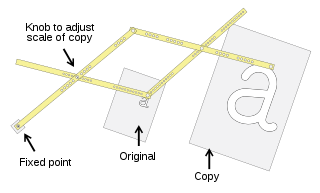

WA pantograph is a mechanical linkage connected in a manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a second pen. If a line drawing is traced by the first point, an identical, enlarged, or miniaturized copy will be drawn by a pen fixed to the other. Using the same principle, different kinds of pantographs are used for other forms of duplication in areas such as sculpture, minting, engraving, and milling.

W

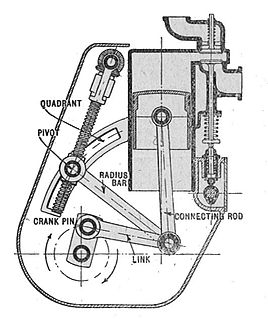

WThe parallel motion is a mechanical linkage invented by the Scottish engineer James Watt in 1784 for the double-acting Watt steam engine. It allows a rod moving practically straight up and down to transmit motion to a beam moving in an arc, without putting significant sideways strain on the rod.

W

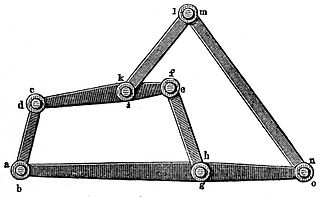

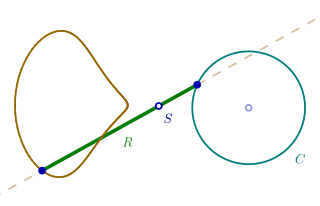

WThe Peaucellier–Lipkin linkage, invented in 1864, was the first true planar straight line mechanism – the first planar linkage capable of transforming rotary motion into perfect straight-line motion, and vice versa. It is named after Charles-Nicolas Peaucellier (1832–1913), a French army officer, and Yom Tov Lipman Lipkin (1846–1876), a Lithuanian Jew and son of the famed Rabbi Israel Salanter.

W

WIn a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or the driving wheels.

W

WThe rhombic drive is a specific method of transferring mechanical energy, or work, used when a single cylinder is used for two separately oscillating pistons.

W

WRoberts Mechanism converts a rotational motion to approximate straight-line motion.

W

WA rod end bearing, also known as a heim joint or rose joint, is a mechanical articulating joint. Such joints are used on the ends of control rods, steering links, tie rods, or anywhere a precision articulating joint is required, and where a clevis end is unsuitable. A ball swivel with an opening through which a bolt or other attaching hardware may pass is pressed into a circular casing with a threaded shaft attached. The threaded portion may be either male or female. The heim joint's advantage is that the ball insert permits the rod or bolt passing through it to be misaligned to a limited degree. A link terminated in two heim joints permits misalignment of their attached shafts.

W

WThe Sarrus linkage, invented in 1853 by Pierre Frédéric Sarrus, is a mechanical linkage to convert a limited circular motion to a linear motion or vice versa without reference guideways. It is a spatial six-bar linkage (6R) with two groups of three parallel adjacent joint-axes.

W

WThe Scotch Yoke is a reciprocating motion mechanism, converting the linear motion of a slider into rotational motion, or vice versa. The piston or other reciprocating part is directly coupled to a sliding yoke with a slot that engages a pin on the rotating part. The location of the piston versus time is simple harmonic motion, i.e., a sine wave having constant amplitude and constant frequency, given a constant rotational speed.

W

WA Scott Russell linkage gives a theoretically linear motion by using a linkage form with three portions of the links all equal, and a rolling or sliding connection. It can be used to form a right-angle change of motion, linear-to-linear.

W

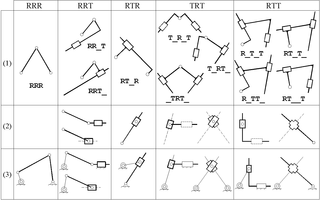

WA six-bar linkage is a one degree-of-freedom mechanism that is constructed from six links and seven joints. An example is the Klann linkage used to drive the legs of a walking machine.

W

WSlider-crank chain inversion arises when the connecting rod, or coupler, of a slider-crank linkage becomes the ground link, so the slider is connected directly to the crank. This inverted slider-crank is the form of a slider-crank linkage that is often used to actuate a hinged joint in construction equipment like a crane or backhoe, as well as to open and close a swinging gate or door.

W

WA slider-crank linkage is a four-link mechanism with three revolute joints and one prismatic, or sliding, joint. The rotation of the crank drives the linear movement the slider, or the expansion of gases against a sliding piston in a cylinder can drive the rotation of the crank.

W

WA steering linkage is the part of an automotive steering system that connects to the front wheels.

W

WIn the late seventeenth century, before the development of the planer and the milling machine, it was extremely difficult to machine straight, flat surfaces. For this reason, good prismatic pairs without backlash were not easy to make. During that era, much thought was given to the problem of attaining a straight-line motion as a part of the coupler curve of a linkage having only revolute connection. Probably the best-known result of this search is the straight line mechanism development by Watt for guiding the piston of early steam engines. Although it does not generate an exact straight line, a good approximation is achieved over a considerable distance of travel.

W

WThe sun and planet gear is a method of converting reciprocating motion to rotary motion and was used in the first rotative beam engines.

W

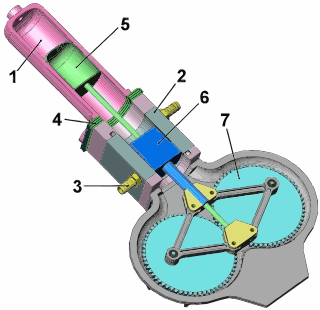

WA swashplate, also known as slant disk, was invented by Anthony George Maldon Michell in 1917. It is a mechanical engineering device used to translate the motion of a rotating shaft into reciprocating motion, or vice versa. The working principles is similar to crankshaft, Scotch yoke, or wobble/nutator/Z-crank drives, in engine designs. It was originally invented to replace a crankshaft, and is one of the most popular concepts used in crankless engines.

W

WWatt's linkage is a type of mechanical linkage invented by James Watt in which the central moving point of the linkage is constrained to travel on a nearly straight line. It was described in Watt's patent specification of 1784 for the Watt steam engine.

W

WWittgenstein's rod is a geometry problem discussed by 20th-century philosopher Ludwig Wittgenstein.