W

WA Barber-Colman knotter is a piece of textile machinery used in a weaving shed. When all the warp carried on the weavers beam has been used, a new beam replaces it. Each end has to pass through the eyes on the existing heddles, and through the existing reed. The knotter takes each new thread and knots it the existing end, which will pull it through the correct healds and reed, saving much time. A good man could do 32 or 33 warps a day.

W

WA cotton gin – meaning "cotton engine" – is a machine that quickly and easily separates cotton fibers from their seeds, enabling much greater productivity than manual cotton separation. The fibers are then processed into various cotton goods such as calico, while any undamaged cotton is used largely for textiles like clothing. The separated seeds may be used to grow more cotton or to produce cottonseed oil.

W

WCotton-spinning machinery refers to machines which process prepared cotton roving into workable yarn or thread. Such machinery can be dated back centuries. During the 18th and 19th centuries, as part of the Industrial Revolution cotton-spinning machinery was developed to bring mass production to the cotton industry. Cotton spinning machinery was installed in large factories, commonly known as cotton mills.

W

WFriction Spinning or Dref Spinning is a textile technology that suitable for spinning coarse counts of yarns and technical core-wrapped yarns. Dref yarns are bulky, with low tensile strength making them suitable for blankets and mop yarns, they can be spun from asbestos, carbon fibres and make filters was water systems. Yarns such as Rayon and Kevlar can be spun using this method. The technology was developed around 1975 by Dr. Ernst Fehrer.

W

WThe Jacquard machine is a device fitted to a loom that simplifies the process of manufacturing textiles with such complex patterns as brocade, damask and matelassé. The resulting ensemble of the loom and Jacquard machine is then called a Jacquard loom. The machine was invented by Joseph Marie Jacquard in 1804, based on earlier inventions by the Frenchmen Basile Bouchon (1725), Jean Baptiste Falcon (1728), and Jacques Vaucanson (1740). The machine was controlled by a "chain of cards"; a number of punched cards laced together into a continuous sequence. Multiple rows of holes were punched on each card, with one complete card corresponding to one row of the design. Several such paper cards, which were generally white in color, can be seen in the images below. Chains, like Bouchon's earlier use of paper tape, allowed sequences of any length to be constructed, not limited by the size of a card.

W

WA kier or keeve is a large circular boiler or vat used in bleaching or scouring cotton fabric. They were also used for processing paper pulp.

W

WA knitting machine is a device used to create knitted fabrics in a semi or fully automated fashion.

W

WLace machines took over the commercial manufacture of lace during the nineteenth century.

W

WThe Lancashire Loom was a semi-automatic power loom invented by James Bullough and William Kenworthy in 1842. Although it is self-acting, it has to be stopped to recharge empty shuttles. It was the mainstay of the Lancashire cotton industry for a century.

W

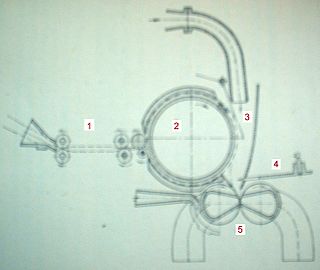

WStationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars, agricultural engines used for ploughing or threshing, marine engines, and the steam turbines used as the mechanism of power generation for most nuclear power plants.

W

WThe Northrop Loom was a fully automatic power loom marketed by George Draper and Sons, Hopedale, Massachusetts beginning in 1895. It was named after James Henry Northrop who invented the shuttle-charging mechanism.

W

WOpen-end spinning is a technology for creating yarn without using a spindle. It was invented and developed in Czechoslovakia in Výzkumný ústav bavlnářský / Cotton Research Institute in Ústí nad Orlicí in 1963.

W

WA power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1787 by Edmund Cartwright and first built in 1787. It was refined over the next 47 years until a design by Kenworthy and Bullough made the operation completely automatic.

W

WA rapier loom is a shuttleless weaving loom in which the filling yarn is carried through the shed of warp yarns to the other side of the loom by finger-like carriers called rapiers.

W

WRing spinning is a method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

W

WThe Roberts loom was a cast-iron power loom introduced by Richard Roberts in 1830. It was the first loom that was more viable than a hand loom and was easily adjustable and reliable, which led to its widespread use in the Lancashire cotton industry.

W

WThe schiffli embroidery machine is a multi-needle, industrial embroidery machine. It was invented by Isaak Gröbli in 1863. It was used to create various types of machine embroidery and certain types of lace. It was especially used in the textile industry of eastern Switzerland and Saxony Germany, but also in the United Kingdom and the United States. Schiffli machines evolved from, and eventually replaced manually operated "hand embroidery" machines. The hand embroidery machine used double ended needles and passed the needles completely through the fabric. Each needle had a single, continuous thread. Whereas the schiffli machine used a lock stitch, the same technique used by the sewing machine. By the early twentieth century schiffli machines had standardized to ten and fifteen meters in width and used more than 600 needles.

W

WA sewing machine is a machine used to sew fabric and materials together with thread. Sewing machines were invented during the first Industrial Revolution to decrease the amount of manual sewing work performed in clothing companies. Since the invention of the first working sewing machine, generally considered to have been the work of Elias Howe and Englishman Thomas Saint in 1790, the sewing machine has greatly improved the efficiency and productivity of the clothing industry.

W

WThe spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

W

WThe spinning jenny is a multi-spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England.

W

WThe spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute. It was invented between 1775 and 1779 by Samuel Crompton. The self-acting (automatic) mule was patented by Richard Roberts in 1825. At its peak there were 50,000,000 mule spindles in Lancashire alone. Modern versions are still in niche production and are used to spin woollen yarns from noble fibres such as cashmere, ultra-fine merino and alpaca for the knitware market.

W

WA stocking frame was a mechanical knitting machine used in the textiles industry. It was invented by William Lee of Calverton near Nottingham in 1589. Its use, known traditionally as framework knitting, was the first major stage in the mechanisation of the textile industry, and played an important part in the early history of the Industrial Revolution. It was adapted to knit cotton and to do ribbing, and by 1800 had been adapted as a lace making machine.

W

WThe technique of sizing a warp was mechanised during the nineteenth century when William Radcliffe and his assistant Thomas Johnson invented the sizing machine. The purpose of introducing size, which is either a starchy substance for cotton or gelatinous mixture for woollen fibre, is to reduce the chances of threads fraying and breaking due to the friction of the weaving process. The size stiffens the thread and helps the fibres lie closely together. Many recipes for size can be found in textile manufacturing books. The recipes include flour, sago, china clay, types of soap, fats and some chemicals.

W

WThe throstle frame was a spinning machine for cotton, wool, and other fibers, differing from a mule in having a continuous action, the processes of drawing, twisting, and winding being carried on simultaneously. It "derived its name from the singing or humming which it occasioned," throstle being a dialect name for the song thrush.

W

WThe water frame is a spinning frame that is powered by a water-wheel. Water frames in general have existed since ancient Egypt times. Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread; this was first used in 1765. The Arkwright water frame was able to spin 96 threads at a time, which was an easier and faster method than ever before. The design was partly based on a spinning machine built for Thomas Highs by clock maker John Kay, who was hired by Arkwright. Being run on water power, it produced stronger and harder yarn than the then-famous "spinning jenny", and propelled the adoption of the modern factory system.