W

WA hybrid turbocharger is an electric turbocharger consisting of a high speed turbine-generator and a high speed electric air compressor. The turbine and compressor are high-speed aeromachines, as in a conventional turbocharger. The electrical motors run at speeds in excess of 120,000 rpm and when used as generators, generate electricity at up to 98.5% electrical efficiency. High electrical efficiency is paramount, because there is no mechanical link between the turbine and compressor. In other words, hybrid turbocharger refers to a series hybrid setup, in which compressor speed and power are independent from turbine speed and power. This design flexibility leads to further improvements in turbine and compressor efficiency, beyond a conventional turbocharger.

W

WA supercharger is an air compressor that increases the pressure or density of air supplied to an internal combustion engine. This gives each intake cycle of the engine more oxygen, letting it burn more fuel and do more work, thus increasing the power output.

W

WAn axial compressor is a gas compressor that can continuously pressurize gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially. This differs from other rotating compressors such as centrifugal compressor, axi-centrifugal compressors and mixed-flow compressors where the fluid flow will include a "radial component" through the compressor. The energy level of the fluid increases as it flows through the compressor due to the action of the rotor blades which exert a torque on the fluid. The stationary blades slow the fluid, converting the circumferential component of flow into pressure. Compressors are typically driven by an electric motor or a steam or a gas turbine.

W

WThe G-Lader is a scroll-type supercharger used in various Volkswagen Passenger Cars models. Its purpose is to increase the motive power output from the internal combustion engine attainable with a given engine displacement. Since it is not enough to simply inject more fuel, as this produces too rich an air-fuel mixture, more intake air has to be added at the same time. This can be achieved with an exhaust-driven turbocharger, or a crankshaft-driven positive displacement compressor. The G-Lader is in the compressor category, since it is crankshaft-driven and does not have the "lag" usually associated with turbocharged engines.

W

WThe Powerplus is a design of supercharger that was used to boost the performance of car engines in the 1930s. It is a mechanically driven positive displacement pump, operating on the sliding-vane principle.

W

WA pressure wave supercharger is a type of supercharger technology that harnesses the pressure waves produced by an internal combustion engine exhaust gas pulses to compress the intake air. Its automotive use is not widespread; the most widely used example is the Comprex, developed by Brown Boveri. Valmet Tractors of Finland were one of the first to use the device when they fitted it to the 411CX engine which powered their 1203 model of 1980. Although it provided a useful increase in performance it was considered too expensive to be incorporated into later models. Ferrari tested such a device during the development of the 126C Formula One car. The system did not lend itself to as tidy an installation as the alternative twin-turbocharger layout, and the car was never raced in this form. A more successful application was in the RF series diesel engine found in the 1988 Mazda 626 Capella; ultimately 150,000 Mazda diesel cars were fitted with a Comprex supercharger. Other users included Peugeot, Opel and Mercedes-Benz. The Greenpeace SmILE concept car uses a Hyprex pressure wave supercharger developed by the Swiss company Wenko AG. NASA uses wave rotors in experiments attempting to increase gas turbine efficiency. The wave rotor is placed between the compressor, combustor, and turbine sections in order to extract more energy from the combustion process.

W

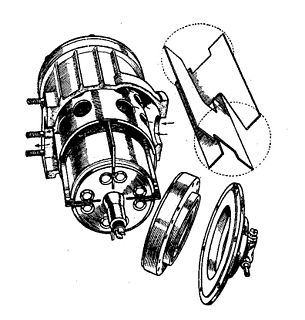

WThe Roots-type blower is a positive displacement lobe pump which operates by pumping a fluid with a pair of meshing lobes resembling a set of stretched gears. Fluid is trapped in pockets surrounding the lobes and carried from the intake side to the exhaust. The most common application of the Roots-type blower has been as the induction device on two-stroke diesel engines, such as those produced by Detroit Diesel and Electro-Motive Diesel. Roots-type blowers are also used to supercharge Otto cycle engines, with the blower being driven from the engine's crankshaft via a toothed or V-belt, a roller chain or a gear train.

W

WThe scroll-type supercharger is a scroll compressor used as a positive displacement orbiting-spiral supercharger. It is a compromise between the more rugged rotating lobe, and the more efficient sliding vane type superchargers, and is considered to offer the highest potential in regard to efficiency, noise and pressure fluctuation.

W

WA rotary-screw compressor is a type of gas compressor, such as an air compressor, that uses a rotary-type positive-displacement mechanism. They are commonly used to replace piston compressors where large volumes of high-pressure air are needed, either for large industrial applications such as chillers, or to operate high-power air tools such as jackhammers and impact wrenches. For smaller rotor sizes the inherent leakage in the rotors becomes much more significant, leading to this type of mechanism being unsuitable for small air compressors.

W

WThe Volkswagen G60 and G40 engines are inline-four cylinder automobile petrol engines, which uses a specific method of forced induction - by way of a scroll-type supercharger. The G60 engine was formerly manufactured by the German automaker Volkswagen Group, and was installed in a limited number and range of 'hot hatch' cars from their Volkswagen Passenger Cars marque from August 1988 to July 1993.