W

WSafety engineering is an engineering discipline which assures that engineered systems provide acceptable levels of safety. It is strongly related to industrial engineering/systems engineering, and the subset system safety engineering. Safety engineering assures that a life-critical system behaves as needed, even when components fail.

W

WAdministrative controls are training, procedure, policy, or shift designs that lessen the threat of a hazard to an individual. Administrative controls typically change the behavior of people rather than removing the actual hazard or providing personal protective equipment (PPE).

W

WA blast damper is used to protect occupants and equipment of a structure against overpressures resultant of an explosion. The blast dampers normally protect air inlets and exhaust penetrations in an otherwise hardened structure. Blast dampers are related or identical to blast valves, the latter name is generally used to describe blast mitigation devices as they relate to nuclear explosions.

W

WA burn pit refers to an area of a deployed military base devoted to open-air combustion of waste. The phrase "burn pit" gained notoriety in the 21st century, especially in U.S. military sites in Iraq and Afghanistan. However, this practice was used well before the War on Terror. Proper waste management practices have reduced the spread of infectious diseases that contributed significantly to mortality and morbidity in military populations in based conflicts. According to the US Army field manual, there are four other ways, outside of burn pits, to dispose of nonhazardous solid waste: incinerators, burial, landfills, and tactical burial. Using open-air burning significantly reduces waste, but increases risk of fire and produces noxious fumes. Due to modern waste in deployed environments, there is plastic, shipping materials, electronic waste, and other material that may emit toxic aerial compounds. Burn pits were heavily criticized and resulted in lawsuit by veterans, Department of Defense Civilians, and military contractors. Global environmental consciousness has especially criticized these instances of large-scale burn pit operation. The effects of burn pits seem to be similar to that of fire debris cleanup.

W

WEngineering controls for nanomaterials are a set of hazard control methods and equipment for workers who interact with nanomaterials. Engineering controls are physical changes to the workplace that isolate workers from hazards, and are considered the most important set of methods for controlling the health and safety hazards of nanomaterials after systems and facilities have been designed.

W

WAn explosion vent or rupture panel is a safety device to protect equipment or buildings against excessive internal, explosion-incurred pressures, by means of pressure relief. An explosion vent will relieve pressure from the instant its opening pressure pstat has been exceeded.

W

WFall protection is the use of controls designed to protect personnel from falling or in the event they do fall, to stop them without causing severe injury. Typically, fall protection is implemented when working at height, but may be relevant when working near any edge, such as near a pit or hole, or performing work on a steep surface.

W

WFault tree analysis (FTA) is a top-down, deductive failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower-level events. This analysis method is mainly used in safety engineering and reliability engineering to understand how systems can fail, to identify the best ways to reduce risk and to determine event rates of a safety accident or a particular system level (functional) failure. FTA is used in the aerospace, nuclear power, chemical and process, pharmaceutical, petrochemical and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to social service system failure. FTA is also used in software engineering for debugging purposes and is closely related to cause-elimination technique used to detect bugs.

W

WA flame arrester, deflagration arrester, or flame trap is a device that stops fuel combustion by extinguishing the flame.

W

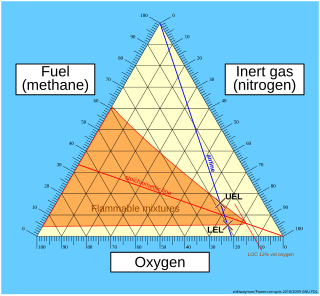

WFlammability diagrams show the control of flammability in mixtures of fuel, oxygen and an inert gas, typically nitrogen. Mixtures of the three gasses are usually depicted in a triangular diagram, known as a ternary plot. Such diagrams are available in the speciality literature. The same information can be depicted in a normal orthogonal diagram, showing only two substances, implicitly using the feature that the sum of all three components is 100 percent. The diagrams below only concerns one fuel; the diagrams can be generalized to mixtures of fuels.

W

WIn occupational safety and health, hand arm vibrations (HAVs) are a specific type of occupational hazard which can lead to hand arm vibration syndrome.

W

WA mixed criticality system is a system containing computer hardware and software that can execute several applications of different criticality, such as safety-critical and non-safety critical, or of different Safety Integrity Level (SIL). Different criticality applications are engineered to different levels of assurance, with high criticality applications being the most costly to design and verify. These kinds of systems are typically embedded in a machine such as an aircraft whose safety must be ensured.

W

WNormal Accidents: Living with High-Risk Technologies is a 1984 book by Yale sociologist Charles Perrow, which provides a detailed analysis of complex systems from a sociological perspective. It was the first to "propose a framework for characterizing complex technological systems such as air traffic, marine traffic, chemical plants, dams, and especially nuclear power plants according to their riskiness". Perrow argues that multiple and unexpected failures are built into society's complex and tightly coupled systems. Such accidents are unavoidable and cannot be designed around.

W

WOccupational safety and health (OSH), also commonly referred to as occupational health and safety (OHS), occupational health, or occupational safety, is a multidisciplinary field concerned with the safety, health, and welfare of people at occupation. These terms also refer to the goals of this field, so their use in the sense of this article was originally an abbreviation of occupational safety and health program/department etc.

W

WAn ohmmeter is an electrical instrument that measures electrical resistance. Micro-ohmmeters make low resistance measurements. Megohmmeters measure large values of resistance. The unit of measurement for resistance is ohms (Ω).

W

WAn opto-isolator is an electronic component that transfers electrical signals between two isolated circuits by using light. Opto-isolators prevent high voltages from affecting the system receiving the signal. Commercially available opto-isolators withstand input-to-output voltages up to 10 kV and voltage transients with speeds up to 25 kV/μs.

W

WPersonal protective equipment (PPE) is protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury or infection. The hazards addressed by protective equipment include physical, electrical, heat, chemicals, biohazards, and airborne particulate matter. Protective equipment may be worn for job-related occupational safety and health purposes, as well as for sports and other recreational activities. "Protective clothing" is applied to traditional categories of clothing, and "protective gear" applies to items such as pads, guards, shields, or masks, and others. PPE suits can be similar in appearance to a cleanroom suit.

W

WPortable appliance testing is the name of a process in the United Kingdom, the Republic of Ireland, New Zealand and Australia by which electrical appliances are routinely checked for safety. The formal term for the process is "in-service inspection & testing of electrical equipment". Testing involves a visual inspection of the equipment and any flexible cables for good condition, and also where required, verification of earthing (grounding) continuity, and a test of the soundness of insulation between the current carrying parts, and any exposed metal that may be touched. The formal limits for pass/fail of these electrical tests vary somewhat depending on the category of equipment being tested.

W

WPredictive maintenance techniques are designed to help determine the condition of in-service equipment in order to estimate when maintenance should be performed. This approach promises cost savings over routine or time-based preventive maintenance, because tasks are performed only when warranted. Thus, it is regarded as condition-based maintenance carried out as suggested by estimations of the degradation state of an item.

W

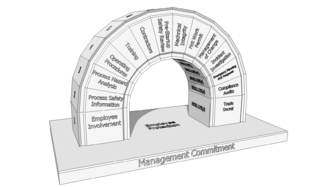

WProcess safety management system is a regulation promulgated by the U.S. Occupational Safety and Health Administration (OSHA). A process is any activity or combination of activities including any use, storage, manufacturing, handling or the on-site movement of highly hazardous chemicals (HHCs) as defined by OSHA and the Environmental Protection Agency.

W

WResistive opto-isolator (RO), also called photoresistive opto-isolator, vactrol, analog opto-isolator or lamp-coupled photocell, is an optoelectronic device consisting of a source and detector of light, which are optically coupled and electrically isolated from each other. The light source is usually a light-emitting diode (LED), a miniature incandescent lamp, or sometimes a neon lamp, whereas the detector is a semiconductor-based photoresistor made of cadmium selenide (CdSe) or cadmium sulfide (CdS). The source and detector are coupled through a transparent glue or through the air.

W

WA safety data sheet (SDS), material safety data sheet (MSDS), or product safety data sheet (PSDS) are documents that list information relating to occupational safety and health for the use of various substances and products. SDSs are a widely used system for cataloguing information on chemicals, chemical compounds, and chemical mixtures. SDS information may include instructions for the safe use and potential hazards associated with a particular material or product, along with spill-handling procedures. The older MSDS formats could vary from source to source within a country depending on national requirements; however, the newer SDS format is internationally standardized.

W

WA safety-critical system (SCS) or life-critical system is a system whose failure or malfunction may result in one of the following outcomes:death or serious injury to people loss or severe damage to equipment/property environmental harm

W

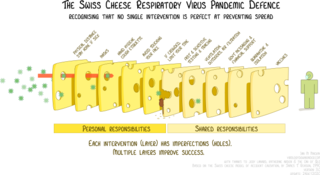

WThe Swiss cheese model of accident causation is a model used in risk analysis and risk management, including aviation safety, engineering, healthcare, emergency service organizations, and as the principle behind layered security, as used in computer security and defense in depth. It likens human systems to multiple slices of Swiss cheese, stacked side by side, in which the risk of a threat becoming a reality is mitigated by the differing layers and types of defenses which are "layered" behind each other. Therefore, in theory, lapses and weaknesses in one defense do not allow a risk to materialize, since other defenses also exist, to prevent a single point of failure. The model was originally formally propounded by Dante Orlandella and James T. Reason of the University of Manchester, and has since gained widespread acceptance. It is sometimes called the "cumulative act effect".

W

WTrapped-key interlocking utilizes locks and keys for sequential control of equipment and machinery to ensure safe operation. Trapped-key interlocks are widely used to ensure safe access to potentially live or dangerous plant or equipment in an industrial setting.

W

WValue tree analysis is a multi-criteria decision-making (MCDM) implement by which the decision-making attributes for each choice to come out with a preference for the decision makes are weighted. Usually, choices' attribute-specific values are aggregated into a complete method. Decision analysts (DAs) distinguished two types of utility. The preferences of value are made among alternatives when there is no uncertainty. Risk preferences solves the attitude of DM to risk taking under uncertainty. This learning package focuses on deterministic choices, namely value theory, and in particular a decision analysis tool called a value tree.

W

WVoluntary Protection Programs (VPP) is an Occupational Safety and Health Administration (OSHA) initiative that encourages private industry and federal agencies to prevent workplace injuries and illnesses through hazard prevention and control, worksite analysis, training; and cooperation between management and workers. VPP enlists worker involvement to achieve injury and illness rates that are below national Bureau of Labor Statistics averages for their respective industries.