W

WThe Able rocket stage was a rocket stage manufactured in the United States by Aerojet as the second of three stages of the Vanguard rocket used in the Vanguard project from 1957 to 1959. The rocket engine used nitric acid and UDMH as rocket propellants. The Able rocket stage was discontinued in 1960. The improved Ablestar version was used as the upper stage of the Thor-Ablestar two stage launcher. The Ablestar second stage was an enlarged version of the Able rocket stage, which gave the Thor-Ablestar a greater payload capacity compared to the earlier Thor-Able. It also incorporated restart capabilities, allowing a multiple-burn trajectory to be flown, further increasing payload, or allowing the rocket to reach different orbits. It was the first rocket to be developed with such a capability and development of the stage took a mere eight months.

W

WAdeline is a concept for a reusable rocket first-stage that would fly itself back to Earth after a launch using drone technology for horizontal landing on a runway. Airbus Defence and Space conceived the design concept.

W

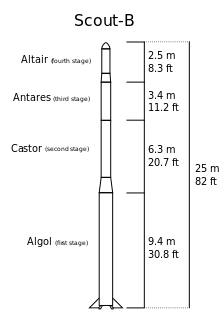

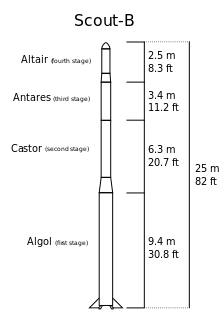

WThe Algol family of solid-fuel rocket stages and boosters built by Aerojet and used on a variety of launch vehicles. It was developed by Aerojet from the earlier Jupiter Senior and the Navy Polaris programs. Upgrades to the Algol motor occurred from 1960 till the retirement of the Scout launch vehicle in 1994.

W

WThe Altair was a solid-fuel rocket with a fiberglass casing, initially developed for use as the third stage of Vanguard rockets. It was manufactured by Allegany Ballistics Laboratory (ABL) as the X-248. It was also sometimes called the Burner 1.

W

WThe Astris was an upper stage developed by ERNO Raumfahrttechnik GmbH and MBB as the third stage of the Europa 1 launch vehicle. It was the German contribution to the project and only flew activated four times. Regrettably, the high failure rate of the three and four stage rocket meant that the project was cancelled.

W

WBlok D is an upper stage used on Soviet and later Russian expendable launch systems, including the N1, Proton-K and Zenit.

W

WBlok E is the propulsion unit of Soviet lunar module LK, developed in 1960s by Yuzhnoye Design Bureau as a part of the manned lunar landing program.

W

WThe Castor family of solid-fuel rocket stages and boosters built by Thiokol and used on a variety of launch vehicles. They were initially developed as the second-stage motor of the Scout rocket. The design was based on the MGM-29 Sergeant, a surface-to-surface missile developed for the United States Army at the Jet Propulsion Laboratory.

W

WThe Centaur is a family of rocket propelled upper stages currently produced by U.S. launch service provider United Launch Alliance, with one main active version and one version under development. The 3.05 m (10.0 ft) diameter Common Centaur/Centaur III flies as the upper stage of the Atlas V launch vehicle, and the 5.4 m (18 ft) diameter Centaur V is being developed as the upper stage of ULA's new Vulcan rocket.

W

WShuttle-Centaur was a proposed Space Shuttle upper stage using the Centaur upper stage rocket. Two variants were produced: Centaur G-Prime, which was planned to launch the Galileo and Ulysses robotic probes to Jupiter, and Centaur G, a shortened version planned for use with United States Department of Defense Milstar satellites and the Magellan Venus probe. The use of the powerful Centaur upper stage allowed for heavier deep space probes, and for them to reach Jupiter sooner, thus saving on battery life and wear and tear to the spacecraft. Support for the project came from the United States Air Force (USAF) and the National Reconnaissance Office (NRO), which asserted that its classified satellites required the power of Centaur. The USAF agreed to pay half the cost of Centaur G.

W

WThe Common Booster Core (CBC) is an American rocket stage, which is used on the Delta IV rocket as part of a modular rocket system. Delta IV rockets flying in the retired Medium and Medium+ configurations each used a single Common Booster Core as their first stage, while the Heavy configuration uses three; one as the first stage and two as boosters. The Common Booster Core is 40.8 metres (134 ft) long, has a diameter of 5.1 metres (17 ft) and is powered by a single RS-68 engine burning liquid hydrogen and liquid oxygen.

W

WThe Centaur is a family of rocket propelled upper stages currently produced by U.S. launch service provider United Launch Alliance, with one main active version and one version under development. The 3.05 m (10.0 ft) diameter Common Centaur/Centaur III flies as the upper stage of the Atlas V launch vehicle, and the 5.4 m (18 ft) diameter Centaur V is being developed as the upper stage of ULA's new Vulcan rocket.

W

WThe Common Core Booster (CCB) is an American rocket stage, which is used as the first stage of the Atlas V rocket as part of its modular design. It was also intended that two additional CCBs would be used as boosters on the Atlas V Heavy, however this configuration has not been developed. Use of a Common Core Booster as the first stage of the Japanese GX was also planned; however, this program was cancelled in late 2009.

W

WThe Delta Cryogenic Second Stage (DCSS) is a family of cryogenic rocket stages used on the Delta III and Delta IV rockets, and which is planned to be used on the Space Launch System Block 1. The stage consists of a cylindrical LH2 tank structurally separated from an oblate spheroid LOX tank. The LH2 tank cylinder carries payload launch loads, while the LOX tank and engine are suspended below within the rocket's inter-stage. The stage is powered by a single Pratt & Whitney RL10B-2 engine, which features an extendable carbon-carbon nozzle to improve specific impulse.

W

WThe Delta-K was an American rocket stage, developed by McDonnell Douglas and Aerojet. It was first used on 27 August 1989 as the second stage for the Delta 4000 series.

W

WThe Exploration Upper Stage (EUS) is being developed as a large second stage for Block 1B of the Space Launch System (SLS), succeeding Block 1's Interim Cryogenic Propulsion Stage. It will be powered by four RL10-C3 engines burning liquid oxygen and liquid hydrogen to produce a total of 440 kN (99,000 lbf) thrust. As of February 2015, the SLS Block 1B will provide thrust of 105 t. The EUS is expected to first fly on Artemis IV in March 2026.

W

WThe Falcon 1 was an expendable launch system privately developed and manufactured by SpaceX during 2006–2009. On 28 September 2008, Falcon 1 became the first privately-developed liquid-fuel launch vehicle to go into orbit around the Earth.

W

WFalcon 9 is a partially reusable two-stage-to-orbit medium-lift launch vehicle designed and manufactured by SpaceX in the United States. Both the first and second stages are powered by SpaceX Merlin engines, using cryogenic liquid oxygen and rocket-grade kerosene (RP-1) as propellants. Its name is derived from the fictional Star Wars spacecraft, the Millennium Falcon, and the nine Merlin engines of the rocket's first stage. The rocket evolved with versions v1.0 (2010–2013), v1.1 (2013–2016), v1.2 "Full Thrust" (2015–present), including the Block 5 Full Thrust variant, flying since May 2018. Unlike most rockets, which are expendable launch systems, since the introduction of the Full Thrust version, Falcon 9 is partially reusable, with the first stage capable of re-entering the atmosphere and landing vertically after separating from the second stage. This feat was achieved for the first time on flight 20 in December 2015.

W

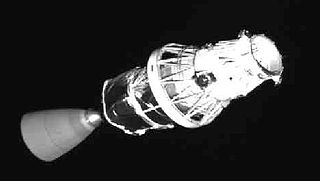

WThe Inertial Upper Stage (IUS), originally designated the Interim Upper Stage, was a two-stage, solid-fueled space launch system developed by Boeing for the United States Air Force beginning in 1976 for raising payloads from low Earth orbit to higher orbits or interplanetary trajectories following launch aboard a Titan 34D or Titan IV rocket as its upper stage, or from the payload bay of the Space Shuttle as a space tug.

W

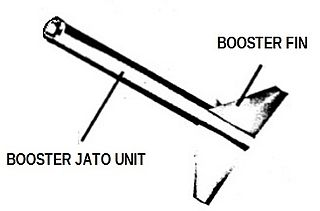

WThe Nike stage or Nike booster, a solid fuel rocket motor, was created by Hercules Aerospace for the Nike Ajax (M5) Nike Hercules (M5E1). It was developed for use as the first stage of the Nike Ajax and Nike Hercules missiles as part of Project Nike.

W

WP80 is a solid-fuel first-stage rocket motor used on the European Space Agency Vega rocket. It is the world's largest and most powerful one-piece solid-fuel rocket engine.

W

WP120 is a solid-fuel first-stage rocket motor in development As of April 2019 by Avio and ArianeGroup through the joint venture Europropulsion on behalf of European Space Agency for use on Vega C and Ariane 6.

W

WThe Payload Assist Module (PAM) is a modular upper stage designed and built by McDonnell Douglas, using Thiokol Star-series solid propellant rocket motors. The PAM was used with the Space Shuttle, Delta, and Titan launchers and carried satellites from low Earth orbit to a geostationary transfer orbit or an interplanetary course. The payload was spin stabilized by being mounted on a rotating plate. Originally developed for the Space Shuttle, different versions of the PAM were developed:PAM-A, development terminated; originally to be used on both the Atlas and Space Shuttle PAM-D, uses a Star-48B rocket motor PAM-DII, uses a Star-63 rocket motor PAM-S (Special) as a kick motor for the space probe Ulysses

W

WThe RM-81 Agena was an American rocket upper stage and satellite bus which was developed by Douglas Aircraft Company initially for the cancelled WS-117L reconnaissance satellite program. Following the split-up of WS-117L into SAMOS and CORONA for image intelligence, and MIDAS for early warning, the Agena was later used as an upper stage, and an integrated component, for several programs, including CORONA reconnaissance satellites and the Agena Target Vehicle (ATV) used to demonstrate rendezvous and docking during Project Gemini. It was used as an upper stage on the Atlas, Thor, Thorad and Titan IIIB rockets, and considered for others including the Space Shuttle and Atlas V. A total of 365 Agena rockets were launched between 28 February 1959 and on 12 February 1987. Only 33 Agenas carried NASA payloads and the vast majority were for United States Department of Defense programs.

W

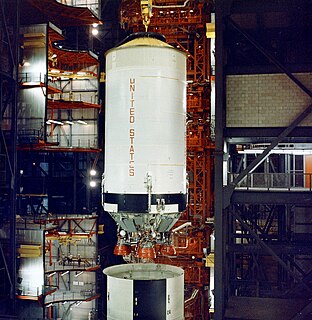

WThe S-I was the first stage of the Saturn I rocket used by NASA for the Apollo program.

W

WThe S-IB stage was the first stage of the Saturn IB launch vehicle, which was used for Earth orbital missions. It was composed of nine propellant containers, eight fins, a thrust structure assembly, eight H-1 rocket engines, and many other components. It also contained the ODOP transponder. The propellant containers consisted of eight Redstone-derived tanks clustered around a Jupiter rocket-derived tank containing LOX. The four outboard engines gimballed to steer the rocket in flight, which required a few more engine components. The S-IB burned for nearly 2.5 minutes before separating at an altitude of 42 miles (68 km).

W

WThe S-IC was the first stage of the American Saturn V rocket. The S-IC stage was manufactured by the Boeing Company. Like the first stages of most rockets, most of its mass of more than 2,000 t (4,400,000 lb) at launch was propellant, in this case RP-1 rocket fuel and liquid oxygen (LOX) oxidizer. It was 42 m (138 ft) tall and 10 m (33 ft) in diameter, and provided 33,000 kN (7,500,000 lbf) of thrust to get the rocket through the first 61 km (38 mi) of ascent. The stage had five F-1 engines in a quincunx arrangement. The center engine was fixed in position, while the four outer engines could be hydraulically gimballed to control the rocket.

W

WThe S-II was the second stage of the Saturn V rocket. It was built by North American Aviation. Using liquid hydrogen (LH2) and liquid oxygen (LOX) it had five J-2 engines in a quincunx pattern. The second stage accelerated the Saturn V through the upper atmosphere with 1,000,000 pounds-force (4.4 MN) of thrust.

W

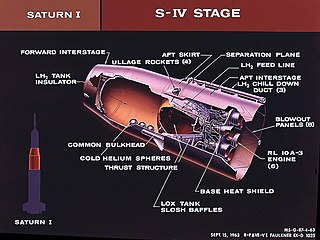

WThe S-IV was the second stage of the Saturn I rocket used by NASA for early flights in the Apollo program.

W

WThe S-IVB was the third stage on the Saturn V and second stage on the Saturn IB launch vehicles. Built by the Douglas Aircraft Company, it had one J-2 rocket engine. For lunar missions it was fired twice: first for Earth orbit insertion after second stage cutoff, and then for translunar injection (TLI).

W

WThe S-V was the third stage of the Saturn I rocket. It was built by Convair. It was designed to use two RL-10A-1 engines fueled by liquid hydrogen (LH2) and liquid oxygen (LOX) in tanks utilizing a common bulkhead to separate the propellants.

W

WStar 48 is a type of solid rocket motor used by many space propulsion and launch vehicle stages. It is used almost exclusively as an upper stage. It was developed primarily by Thiokol Propulsion, and is now manufactured by Orbital ATK, which purchased Thiokol in 2001. A Star 48B stage is also one of the few man-made items sent on escape trajectories out of the Solar System, although it is derelict since its use. The Star 48B variant was the PAM-D upper stage used on the now retired Delta II rocket.

W

WThe Transfer Orbit Stage (TOS) was an upper stage developed by Martin Marietta for Orbital Sciences Corporation during the late 1980s and early 1990s. The TOS was designed to be a lower-cost alternative to Inertial Upper Stage and Centaur G upper stages. The TOS was designed to be deployed by the Titan 34D, Commercial Titan III and Space Shuttle.

W

WTranstage, given the United States Air Force designation SSB-10A, was an American upper stage used on Titan III rockets, developed by Martin Marietta and Aerojet.

W

WZefiro is a family of solid-fuel rocket motor developed by Avio and used on the European Space Agency Vega rocket. The name Zefiro derives from the acronym ZEro FIrst stage ROcket, conceived when this motor was intended to be used as first and second stages of San Marco program of the Italian Space Agency (ASI). After its intended use as booster was shelved the acronym was dropped and only the reference to the Greek god of the west wind Zephyrus remained.