W

WAn air classifier is an industrial machine which separates materials by a combination of size, shape, and density.

W

WA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

W

WA blowout preventer (BOP) is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves.

W

WVibratory bowl feeders are common devices used to feed individual component parts for assembly on industrial production lines. They are used when a randomly sorted bulk package of small components must be fed into another machine one-by-one, oriented in a particular direction.

W

WThe Buell dryer, also known as the "turbo shelf" dryer, is an indirect heated industrial dryer once widely used in the Cornwall and Devon china clay mining industry. The Buell dryer was introduced to the china clay industry by English Clays Lovering Pochin & Co. Ltd for their china clay drying plants in Cornwall and Devon, as part of the mechanization and modernization of the industry, which up to that point had been using the same primitive processing methods for almost 100 years.

W

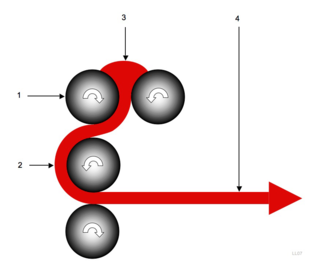

WA calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, or plastics. Calender rolls are also used to form some types of plastic films and to apply coatings. Some calender rolls are heated or cooled as needed. Calenders are sometimes mis-spelled calendars.

W

WA cargo net is a type of net. It is usually square or rectangle, but sometimes round, made of thick rope, with cinch ropes extending from the corners, and in some designs, the edges. It is named for its use in transferring cargo to and from ships.

W

WA case sealer or box sealer is a piece of equipment used for closing or sealing corrugated boxes. It is most commonly used for regular slotted containers (RSC) and can involve adhesive, box sealing tape, or Gummed tape.

W

WA checkweigher is an automatic or manual machine for checking the weight of packaged commodities. It is normally found at the offgoing end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Any packs that are outside the tolerance are taken out of line automatically.

W

WIn the oil and gas industries, coiled tubing refers to a very long metal pipe, normally 1 to 3.25 in in diameter which is supplied spooled on a large reel. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the drilling derrick on the oil platform, which is used to support the surface equipment, although on platforms with no drilling facilities a self-supporting tower can be used instead. For coiled tubing operations on sub-sea wells a mobile offshore drilling unit (MODU) e.g. semi-submersible, drillship etc. has to be utilized to support all the surface equipment and personnel, whereas wireline can be carried out from a smaller and cheaper intervention vessel. Onshore, they can be run using smaller service rigs, and for light operations a mobile self-contained coiled tubing rig can be used.

W

WCoiled tubing umbilicals are a type of piping used in oil and gas wells.

W

WA concrete mixer is a device that homogeneously combines cement, aggregate such as sand or gravel, and water to form concrete. A typical concrete mixer uses a revolving drum to mix the components. For smaller volume works, portable concrete mixers are often used so that the concrete can be made at the construction site, giving the workers ample time to use the concrete before it hardens. An alternative to a machine is mixing concrete by hand. This is usually done in a wheelbarrow; however, several companies have recently begun to sell modified tarps for this purpose.

W

WA derrick is a lifting device composed at minimum of one guyed mast, as in a gin pole, which may be articulated over a load by adjusting its guys. Most derricks have at least two components, either a guyed mast or self-supporting tower, and a boom hinged at its base to provide articulation, as in a stiffleg derrick.

W

WA fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run.

W

WA four-slide, also known as a multislide, multi-slide, or four-way, is a metalworking machine tool used in the high-volume manufacture of small stamped components from bar or wire stock. The press is most simply described as a horizontal stamping press that uses cams to control tools. The machine is used for progressive or transfer stamping operations.

W

WA horn analyzer is an test instrument dedicated to determine the resonance and anti-resonance frequencies of ultrasonic parts such as transducers, converters, horns/sonotrodes and acoustic stacks, which are used for ultrasonic welding, cutting, cleaning, medical and industrial applications. In addition, digital horn analyzers are able to determine the electrical impedance of piezoelectric materials, the Butterworth-Van Dyke (BVD)equivalent circuit and the mechanical quality fator (Qm).

W

WThe hydromill trench cutter is a type of construction equipment designed to dig the narrow but deep trenches used in the casting of slurry walls. Typically, it is a cutter attachment mounted on a crawler crane base machine, with different types of hose handling systems. The machine excavates by cutting the soil using two cutting wheels, while a powerful pump extracts the loose material mixed with some of the slurry, typically bentonite.

W

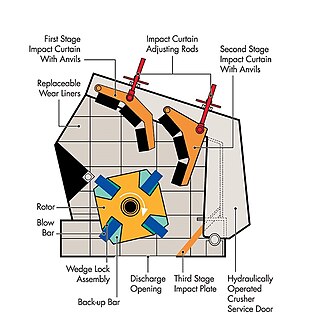

WImpact mills are one of two general classes of milling devices used to reduce the particle size of a material.

W

WIndustrial dryers are used to efficiently process large quantities of bulk materials that need reduced moisture levels. Depending on the amount and the makeup of material needing to be dried, industrial dryers come in many different models constructed specifically for the type and quantity of material to be processed. The most common types of industrial dryers are fluidized bed dryers, rotary dryers, rolling bed dryers, conduction dryers, convection dryers, pharmaceutical dryers, suspension/paste dryers, toroidal bed or TORBED dryers and dispersion dryers. Various factors are considered in determining the correct type of dryer for any given application, including the material to be dried, drying process requirements, production requirements, final product quality requirements and available facility space.

W

WA mezzanine is, strictly speaking, an intermediate floor in a building which is partly open to the double-height ceilinged floor below, or which does not extend over the whole floorspace of the building. However, the term is often used loosely for the floor above the ground floor, especially where a very high original ground floor has been split horizontally into two floors.

A multiple-effect evaporator, as defined in chemical engineering, is an apparatus for efficiently using the heat from steam to evaporate water. In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapor boiled off in one vessel can be used to heat the next, and only the first vessel requires an external source of heat. While in theory, evaporators may be built with an arbitrarily large number of stages, evaporators with more than four stages are rarely practical except in systems where the liquor is the desired product such as in chemical recovery systems where up to seven effects are used.

W

WAn optical comparator or profile projector is a device that applies the principles of optics to the inspection of manufactured parts. In a comparator, the magnified silhouette of a part is projected upon the screen, and the dimensions and geometry of the part are measured against prescribed limits. It is a useful item in a small parts machine shop or production line for the quality control inspection team.

W

WA palletizer or palletiser is a machine which provides automatic means for stacking cases of goods or products onto a pallet.

W

WA presence sensing device (PSD) is a safety device for press brakes and similar metal-bending machines. The device operator often holds the sheet metal work-piece in one place while another portion of the piece is being formed in the die. If a foreign object is detected, the PSD immediately retracts the die or stops the motion of the ram. PSDs protect the operator and other employees in the area.

W

WRecovery boiler is the part of Kraft process of pulping where chemicals for white liquor are recovered and reformed from black liquor, which contains lignin from previously processed wood. The black liquor is burned, generating heat, which is usually used in the process or in making electricity, much as in a conventional steam power plant. The invention of the recovery boiler by G.H. Tomlinson in the early 1930s was a milestone in the advancement of the kraft process.

W

WA recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat. Generally, they are used to extract heat from the exhaust and use it to preheat air entering the combustion system. In this way they use waste energy to heat the air, offsetting some of the fuel, and thereby improves the energy efficiency of the system as a whole.

W

WRolling bed dryers are used for efficiently processing large amounts of material that need their respective moisture levels reduced. Rolling bed dryers are most often used for drying wood chips and organic residues and are most often utilized in the biomass, waste/recycling, wood particle board, pellet, and biofuel industries.

W

WA run-around coil is a type of energy recovery heat exchanger most often positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, to recover the heat energy. Generally, it refers to any intermediate stream used to transfer heat between two streams that are not directly connected for reasons of safety or practicality. It may also be referred to as a run-around loop, a pump-around coil or a liquid coupled heat exchanger.

W

WA screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, and bone meal, municipal solid waste, and many others. The first type of screw conveyor was the Archimedes' screw, used since ancient times to pump irrigation water.

W

WA shadow board is a device for organizing a set of tools; the board defines where particular tools should be placed when they are not in use. Shadow boards have the outlines of a work station's tools marked on them, allowing operators to identify quickly which tools are in use or missing. The boards are commonly located near the work station where the tools are used. Shadow boards are often used in the manufacturing environment to improve a facility's lean six sigma capabilities.

W

WA thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of an air-handling system or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel.

W

WA tool is an object used to extend the ability of an individual to modify features of the surrounding environment. Although many animals use simple tools, only human beings, whose use of stone tools dates back hundreds of millennia, have been observed using tools to make other tools. The set of tools required to perform different tasks that are part of the same activity is called gear or equipment.

W

WA trickling filter is a type of wastewater treatment system. It consists of a fixed bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (biofilm) to grow, covering the bed of media. Aerobic conditions are maintained by splashing, diffusion, and either by forced-air flowing through the bed or natural convection of air if the filter medium is porous.

W

WThe turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable. It evolved from earlier lathes with the addition of the turret, which is an indexable toolholder that allows multiple cutting operations to be performed, each with a different cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via electronically-directed servomechanisms for computer numerical control lathes.

W

WThe Ursa Major at Black Thunder Coal Mine, Wyoming, is the largest dragline excavator currently in use in North America and the third largest ever built. It is a Bucyrus-Erie 2570WS model and cost US$50 million. The Ursa Major was one of five large walking draglines operated at Black Thunder, with the next two largest in the dragline fleet being Thor, a B-E 1570W - which has a 97.5m boom and a 69m³ bucket - and Walking Stick, a B-E 1300W with a 92m boom and a 34m³ bucket.

W

WA vacuum truck or vacuum tanker is a tank truck that has a pump and a tank. The pump is designed to pneumatically suck liquids, sludges, slurries, or the like from a location into the tank of the truck. The objective is to enable transport of the liquid material via road to another location. Vacuum trucks transport the collected material to a treatment or disposal site, for example a sewage treatment plant.

W

WA vapor–liquid separator is a device used in several industrial applications to separate a vapor–liquid mixture.

W

WA variable rate feeder is a piece of industrial control equipment used to deliver solid material at a known rate into some process.

W

WA wheel washing system is a device for cleaning the tires of trucks when they are leaving a site, to control and eliminate the pollution of public roads. The installation can be made in or above the ground for either temporary or permanent applications. There are two types of wheel washing systems: roller and drive-through systems.

W

WWire rope spooling technology is the technology to prevent wire rope getting snagged when spooled, especially in multiple layers on a drum.