W

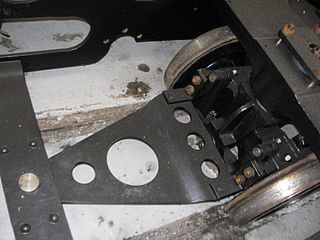

WThe Adams axle is a form of radial axle for rail locomotives that enable them to negotiate curves more easily. It was invented by William Bridges Adams and patented in 1865. The invention uses axle boxes that slide on an arc in shaped horn blocks, so allowing the axle to slide out to either side. This is similar to the movement of a Bissell truck, but with the notional centre point of the curve being where the pivot of the truck would be. This design, using slide bearings, is more expensive than one employing a shaft, but takes up less space.

W

WThe 5AT Advanced Technology steam locomotive was a conceptual design conceived by the British engineer David Wardale, and first described in his definitive work on modern steam, The Red Devil and Other Tales from the Age of Steam.

W

WAdvanced steam technology reflects an approach to the technical development of the steam engine intended for a wider variety of applications than has recently been the case. Particular attention has been given to endemic problems that led to the demise of steam power in small- to medium-scale commercial applications: excessive pollution, maintenance costs, labour-intensive operation, low power/weight ratio, and low overall thermal efficiency; where steam power has generally now been superseded by the internal combustion engine or by electrical power drawn from an electrical grid. The only steam installations that are in widespread use are the highly efficient thermal power plants used for generating electricity on a large scale. In contrast, the proposed steam engines may be for stationary, road, rail or marine use.

W

WAn automatic lubricator, is a device fitted to a steam engine to supply lubricating oil to the cylinders and, sometimes, the bearings and axle box mountings as well. There are various types of automatic lubricator, which include various designs of displacement, hydrostatic and mechanical lubricators.

W

WThe Beugniot lever (Beugniot-Hebel) is a mechanical device used on a number of locomotives to improve curve running. It was named after its inventor Édouard Beugniot.

W

WA Bissell or Bissel truck is a single-axle bogie which pivots towards the centre of a steam locomotive to enable it to negotiate curves more easily. Invented in 1857 by Levi Bissell and usually then known as a pony truck, it is a very simple and common means of designing a carrying wheel.

W

WBoiler blowdown is water intentionally wasted from a boiler to avoid concentration of impurities during continuing evaporation of steam. The water is blown out of the boiler with some force by steam pressure within the boiler. Bottom blowdown used with early boilers caused abrupt downward adjustment of boiler water level and was customarily expelled downward to avoid the safety hazard of showering hot water on nearby individuals.

W

WBoiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the main condenser. From the condenser it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feed water is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle.

W

WThe Bury Bar Frame locomotive was an early type of steam locomotive, developed at the works of Edward Bury and Company, later named Bury, Curtis, and Kennedy. By the 1830s, the railway locomotive had evolved into three basic types - those developed by Robert Stephenson, Timothy Hackworth and Edward Bury.

W

WA Cartazzi axle is a design of leading or trailing wheel support used worldwide. The design was used extensively on the former LNER's Pacific steam locomotives and named after its inventor F.I. Cartazzi, formerly of the Great Northern Railway. It should not be confused with a pony truck as it does not pivot at all. The axle does, however, have sideways play built in to accommodate tight curves. Cartazzi's design causes the weight of the locomotive to exert a self-centring action on the trailing wheels.

W

WThe chimney is the part of a steam locomotive through which smoke leaves the boiler. Steam locomotive exhaust systems typically vent cylinder exhaust through the chimney to enhance draught through the boiler. Chimneys are designed to carry exhaust steam and smoke clear of the driver's line of sight while remaining short enough to clear overhead structures. Some chimneys included features to avoid dispersing sparks.

W

WA compound steam engine unit is a type of steam engine where steam is expanded in two or more stages. A typical arrangement for a compound engine is that the steam is first expanded in a high-pressure (HP) cylinder, then having given up heat and losing pressure, it exhausts directly into one or more larger-volume low-pressure (LP) cylinders. Multiple-expansion engines employ additional cylinders, of progressively lower pressure, to extract further energy from the steam.

W

WA condensing steam locomotive is a type of locomotive designed to recover exhaust steam, either in order to improve range between taking on boiler water, or to reduce emission of steam inside enclosed spaces. The apparatus takes the exhaust steam that would normally be used to produce a draft for the firebox, and routes it through a heat exchanger, into the boiler water tanks. Installations vary depending on the purpose, design and the type of locomotive to which it is fitted. It differs from the usual closed cycle condensing steam engine, in that the function of the condenser is primarily either to recover water, or to avoid excessive emissions to the atmosphere, rather than maintaining a vacuum to improve both efficiency and power.

W

WA coupling rod or side rod connects the driving wheels of a locomotive. Steam locomotives in particular usually have them, but some diesel and electric locomotives, especially older ones and shunters, also have them. The coupling rods transfer the power of drive to all wheels.

W

WThe cylinder is the power-producing element of the steam engine powering a steam locomotive. The cylinder is made pressure-tight with end covers and a piston; a valve distributes the steam to the ends of the cylinder. Cylinders were cast in iron and later made of steel. The cylinder casting includes other features such as valve ports and mounting feet. The last big American locomotives incorporated the cylinders as part of huge one-piece steel castings that were the main frame of the locomotive. Renewable wearing surfaces were needed inside the cylinders and provided by cast-iron bushings.

W

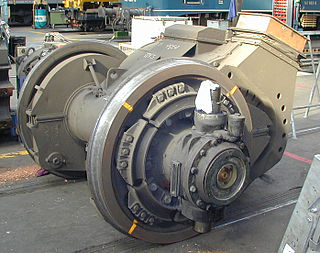

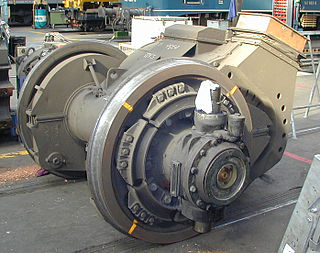

WOn a steam locomotive, a driving wheel is a powered wheel which is driven by the locomotive's pistons. On a conventional, non-articulated locomotive, the driving wheels are all coupled together with side rods ; normally one pair is directly driven by the main rod which is connected to the end of the piston rod; power is transmitted to the others through the side rods.

W

WA duplex locomotive is a steam locomotive that divides the driving force on its wheels by using two pairs of cylinders rigidly mounted to a single locomotive frame; it is not an articulated locomotive. The concept was first used in France in 1863, but was particularly developed in the early 1930s by the Baldwin Locomotive Works, the largest commercial builder of steam locomotives in North America, under the supervision of its then chief engineer, Ralph P. Johnson.

W

WOn a steam locomotive, a driving wheel is a powered wheel which is driven by the locomotive's pistons. On a conventional, non-articulated locomotive, the driving wheels are all coupled together with side rods ; normally one pair is directly driven by the main rod which is connected to the end of the piston rod; power is transmitted to the others through the side rods.

W

WA fusible plug is a threaded metal cylinder usually of bronze, brass or gunmetal, with a tapered hole drilled completely through its length. This hole is sealed with a metal of low melting point that flows away if a pre-determined, high temperature is reached. The initial use of the fusible plug was as a safety precaution against low water levels in steam engine boilers, but later applications extended its use to other closed vessels, such as air conditioning systems and tanks for transporting corrosive or liquefied petroleum gasses.

W

WA Giesl ejector is a suction draught system for steam locomotives that works on the same principle as a feedwater injector. This ejector was invented in 1951 by the Austrian engineer, Dr. Adolph Giesl-Gieslingen. The Giesl ejector ensures improved suction draught and a correspondingly better use of energy. The existing blastpipe in a locomotive is replaced by several, small, fan-shaped, diverging blast pipes, from which the diffuser gets its flat, long, drawn-out shape.

W

WThe Gölsdorf axle system is used on railway Gölsdorf locomotives to achieve quiet running and low wear-and-tear when negotiating curves. The axle system comprises a combination of fixed axles and axles that can slide transversely, all within a single, rigid locomotive frame. The system was invented by a young Austrian locomotive builder, Karl Gölsdorf, around the end of the 19th century. The first locomotive to use this principle entered service in 1897.

W

WAn injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts, excepting a valve to control inlet flow. A steam injector is a typical application of the principle used to deliver cold water to a boiler against its own pressure, using its own live or exhaust steam, replacing any mechanical pump. When first developed, its operation was intriguing because it seemed paradoxical, almost like perpetual motion, but it was later explained using thermodynamics. Other types of injector may use other pressurised motive fluids such as air.

W

WA Krauss-Helmholtz bogie (Krauss-Helmholtz-Lenkgestell) is a mechanism used on steam locomotives and some electric locomotives to improve curve running.

W

WThe Kuhn slide is part of a modified Walschaerts (German:Heusinger) valve gear on steam locomotives and is named after its inventor, Michael Kuhn (1851–1903). The term is also used to refer to this particular type of Walschaerts valve gear system as a whole.

W

WThe Kylchap steam locomotive exhaust system was designed and patented by French steam engineer André Chapelon, using a second-stage nozzle designed by the Finnish engineer Kyösti Kylälä and known as the Kylälä spreader; thus the name KylChap for this design.

W

WThe Lempor ejector is a steam locomotive exhaust system developed by noted Argentine locomotive engineer Livio Dante Porta. The name is a combination of those of Maurice Lemaître, Belgian locomotive engineer, and Porta.

W

WA mechanical stoker is a mechanical system that feeds solid fuel like coal, coke or anthracite into the furnace of a steam boiler. They are common on steam locomotives after 1900 and are also used on ships and power stations. Known now as a spreader stoker they remain in use today especially in furnaces fueled by wood pellets or refuse.

W

WA steam motor is a form of steam engine used for light locomotives. They represented one of the final developments of the steam locomotive, in the final decades of the widespread use of steam power.

W

WThe 1815 Philadelphia train accident occurred on 31 July 1815, in Philadelphia, County Durham, England, when an early experimental railway locomotive, Brunton's Mechanical Traveller, suffered a boiler explosion. This engine, also known as the Steam Horse, ran on four wheels but was pushed by mechanical feet. This was both the first recorded boiler explosion and the first railway accident causing major loss of life, as 16 people were killed [some sources state 13].

W

WIn a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or the driving wheels.

W

WA piston valve is a device used to control the motion of a fluid along a tube or pipe by means of the linear motion of a piston within a chamber or cylinder.

W

WPiston valves are one form of valve used to control the flow of steam within a steam engine or locomotive. They control the admission of steam into the cylinders and its subsequent exhausting, enabling a locomotive to move under its own power. The valve consists of two piston heads on a common spindle moving inside a steam chest, which is essentially a mini-cylinder located either above or below the main cylinders of the locomotive.

W

WPriming is a condition in the boiler of a steam locomotive in which water is carried over into the steam delivery. It may be caused by impurities in the water, which foams up as it boils, or simply too high a water level. It is harmful to the valves and pistons, as lubrication is washed away, and can be dangerous as any water collecting in the cylinders is not compressible and if trapped may fracture the cylinder head or piston.

W

WIn railway terminology the term running gear refers to those components of a railway vehicle that run passively on the rails, unlike those of the driving gear. Traditionally these are the wheels, axles, axle boxes, springs and vehicle frame of a railway locomotive or wagon. The running gear of a modern railway vehicle comprises, in most instances, a bogie frame with two wheelsets. However there are also wagons with single axles and even individual wheels. Since in modern times, locomotives no longer require separate driving and carrying axles, as was formerly common with steam locomotives, but usually have bogies where all axles are driven, the term running gear is (inaccurately) superseding the term 'driving gear' in some parts of the world.

W

WA sandbox is a container on most locomotives, multiple units and trams that holds sand, which is dropped on the rail in front of the driving wheels in wet and slippery conditions and on steep grades to improve traction.

W

WSmoke deflectors, sometimes called "blinkers" in the UK because of their strong resemblance to the blinkers used on horses, and "elephant ears" in US railway slang, are vertical plates attached to each side of the smokebox at the front of a steam locomotive. They are designed to lift smoke away from the locomotive at speed so that the driver has better visibility. On the South Australian Railways they are called "valances".

W

WA smokebox is one of the major basic parts of a steam locomotive exhaust system. Smoke and hot gases pass from the firebox through tubes where they pass heat to the surrounding water in the boiler. The smoke then enters the smokebox, and is exhausted to the atmosphere through the chimney. Early locomotives had no smokebox and relied on a long chimney to provide natural draught for the fire but smokeboxes were soon included in the design for two main reasons. Firstly and most importantly, the blast of exhaust steam from the cylinders, when directed upwards through an airtight smokebox with an appropriate design of exhaust nozzle, effectively draws hot gases through the boiler tubes and flues and, consequently, fresh combustion air into the firebox. Secondly, the smokebox provides a convenient collection point for ash and cinders ("char") drawn through the boiler tubes, which can be easily cleaned out at the end of a working day. Without a smokebox, all char must pass up the chimney or will collect in the tubes and flues themselves, gradually blocking them.

W

WA steam locomotive is a type of railway locomotive that produces its pulling power through a steam engine. These locomotives are fuelled by burning combustible material—usually coal, wood, or oil—to produce steam in a boiler. The steam moves reciprocating pistons which are mechanically connected to the locomotive's main wheels (drivers). Both fuel and water supplies are carried with the locomotive, either on the locomotive itself or in wagons (tenders) pulled behind.

W

WThis article is a glossary of the main components found on a typical steam locomotive.

W

WThe steam locomotive exhaust system consists of those parts of a steam locomotive which together discharge exhaust steam from the cylinders in order to increase the draught through the fire. It usually consists of the blastpipe, smokebox, and chimney, although later designs also include second and third stage nozzles.

W

WA tender or coal-car is a special rail vehicle hauled by a steam locomotive containing its fuel and water. Steam locomotives consume large quantities of water compared to the quantity of fuel, so their tenders are necessary to keep them running over long distances. A locomotive that pulls a tender is called a tender locomotive. Locomotives that do not have tenders and carry all their fuel and water on board the locomotive itself are called tank locomotives.

W

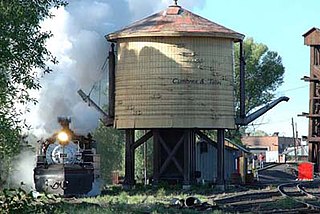

WA water trough, or track pan is a device to enable a steam locomotive to replenish its water supply while in motion. It consists of a long trough filled with water, lying between the rails. When a steam locomotive passes over the trough, a water scoop can be lowered, and the speed of forward motion forces water into the scoop, up the scoop pipe and into the tanks or locomotive tender.

W

WThe Trofimoff valve is a springless pressure-compensation piston valve for steam locomotives.

W

WAn automatic lubricator, is a device fitted to a steam engine to supply lubricating oil to the cylinders and, sometimes, the bearings and axle box mountings as well. There are various types of automatic lubricator, which include various designs of displacement, hydrostatic and mechanical lubricators.

W

WA Water Crane is a device used for delivering a large volume of water into the tank or tender of a steam locomotive. The device is also called a Water Column in the United States and Australia. As a steam locomotive consumes large quantities of water, water cranes were a vital part of railway station equipment, often situated at the end of a platform, so that water could be refilled during a stop at the station.

W

WA Water Crane is a device used for delivering a large volume of water into the tank or tender of a steam locomotive. The device is also called a Water Column in the United States and Australia. As a steam locomotive consumes large quantities of water, water cranes were a vital part of railway station equipment, often situated at the end of a platform, so that water could be refilled during a stop at the station.

W

WA water stop or water station on a railroad is a place where steam trains stop to replenish water. The stopping of the train itself is also referred to as a "water stop". The term originates from the times of steam engines when large amounts of water were essential. Also known as wood and water stops or coal and water stops, since it was reasonable to replenish engines with fuel as well when adding water to the boiler.

W

WA water trough, or track pan is a device to enable a steam locomotive to replenish its water supply while in motion. It consists of a long trough filled with water, lying between the rails. When a steam locomotive passes over the trough, a water scoop can be lowered, and the speed of forward motion forces water into the scoop, up the scoop pipe and into the tanks or locomotive tender.