W

WEngineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibres, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material. The panels vary in size but can range upwards of 64 by 8 feet and in the case of cross-laminated timber (CLT) can be of any thickness from a few inches to 16 inches or more. These products are engineered to precise design specifications, which are tested to meet national or international standards and provide uniformity and predictability in their structural performance. Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. The products can be used for joists and beams that replace steel in many building projects. The term mass timber describes a group of building materials that can replace concrete assemblies. Broad-base adoption of mass timber and their substitution for steel and concrete in new mid-rise construction projects over the next few decades has the potential of turning timber buildings into a global carbon sink, which could help mitigate climate change.

W

WMolded plywood is the term for two- or three-dimensionally shaped products from multiple veneer layers that are glued together through heat and pressure in a pressing tool. The veneer layers are arranged crosswise at an angle of 90 degrees. Molded wood is used for flat furniture components such as seats, backrests and seat shells. When the veneer layers are arranged in the same direction, it is called laminated wood. It is used for armrests and chair frames. After pressing, the blanks are processed mechanically. A particular feature is the ability to produce different variations of shapes from the blanks. Due to its immense strength and low weight, molded wood is particularly suitable for interior decoration, seating furniture, bed slats, skateboards and vehicle construction.

W

WBrettstapel, also known as dowellam, is a massive timber construction system, fabricated exclusively from softwood timber posts connected with hardwood timber dowels. It is a relatively simple method of construction that exploits low grade timber, not normally suitable for use in construction, to form load bearing solid timber wall, floor and roof panels.

W

WA cement board is a combination of cement and reinforcing fibers formed into sheets, of varying thickness that are typically used as a tile backing board. Cement board can be nailed or screwed to wood or steel studs to create a substrate for vertical tile and attached horizontally to plywood for tile floors, kitchen counters and backsplashes. It can be used on the exterior of buildings as a base for exterior plaster (stucco) systems and sometimes as the finish system itself.

W

WCross-laminated timber (CLT) is a wood panel product made from gluing together layers of solid-sawn lumber, i.e., lumber cut from a single log. Each layer of boards is usually oriented perpendicular to adjacent layers and glued on the wide faces of each board, usually in a symmetric way so that the outer layers have the same orientation. An odd number of layers is most common, but there are configurations with even numbers as well. Regular timber is an anisotropic material, meaning that the physical properties change depending on the direction at which the force is applied. By gluing layers of wood at right angles, the panel is able to achieve better structural rigidity in both directions. It is similar to plywood but with distinctively thicker laminations.

W

WFiber cement siding is a building material used to cover the exterior of a building in both commercial and domestic applications. Fiber cement is a composite material made of cement reinforced with cellulose fibers. Originally, asbestos was used as the reinforcing material but, due to safety concerns, that was replaced by cellulose in the 1980s. Fiber cement board may come pre-painted or pre-stained or can be done so after its installation.

W

WFiberboard or fibreboard is a type of engineered wood product that is made out of wood fibers. Types of fiberboard include particle board or low-density fiberboard (LDF), medium-density fiberboard (MDF), and hardboard.

W

WGlued laminated timber, also abbreviated glulam, is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable, moisture-resistant structural adhesives. In North America, the material providing the laminations is termed laminating stock or lamstock.

W

WHardboard, also called high-density fiberboard (HDF), is a type of fiberboard, which is an engineered wood product. It is used in furniture and in the construction industry.

W

WHybrid wood or wood hybrid systems (WHS) is a multilayer composite material, composed on the surface of a skin made of composite wood (WPC) adhering to an underneath structural core, in general aluminum. Invented in Japan in 2008, this technological evolution is based on wood composite technology which was conceived in 1972 by Sadao Nishibori and patented in 1983 to substitute threatened exotic wood species. WHS are not fibre-reinforced plastic (FRP).

W

WAn engineered wood joist, more commonly known as an I-joist, is a product designed to eliminate problems that occur with conventional wood joists. Invented in 1969, the I-joist is an engineered wood product that has great strength in relation to its size and weight. The biggest notable difference from dimensional lumber is that the I-joist carries heavy loads with less lumber than a dimensional solid wood joist. As of 2005, approximately 50% of all wood light framed floors used I-joists. I-joists were designed to help eliminate typical problems that come with using solid lumber as joists.

W

WLaminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. It is typically used for headers, beams, rimboard, and edge-forming material. LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter, and more uniform. Due to its composite nature, it is much less likely than conventional lumber to warp, twist, bow, or shrink. LVL is a type of structural composite lumber, comparable to Glued laminated timber (Glulam) but with a higher allowable stress.

W

WMasonite is a type of hardboard, a kind of engineered wood, which is made of steam-cooked and pressure-molded wood fibers in a process patented by William H. Mason. It is also called Quartrboard, Isorel, hernit, karlit, torex, treetex, and pressboard.

W

WMedium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally more dense than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger, and more dense, than particle board.

W

WOriented strand board (OSB) is a type of engineered wood similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. It was invented by Armin Elmendorf in California in 1963. OSB may have a rough and variegated surface with the individual strips of around 2.5 cm × 15 cm, lying unevenly across each other, and is produced in a variety of types and thicknesses.

W

WPapercrete is a building material that consists of re-pulped paper fiber with Portland cement or clay and/or other soil added. First patented in 1928, it was revived during the 1980s. Although perceived as an environmentally friendly material due to the significant recycled content, this is offset by the presence of cement. The material lacks standardisation, and proper use therefore requires care and experience. Eric Patterson and Mike McCain, who have been credited with independently "inventing" papercrete, have both contributed considerably to research into machinery to make it and ways of using it for building.

W

WParallel-strand lumber (PSL) is a form of engineered wood made from parallel wood strands bonded together with adhesive. It is used for beams, headers, columns, and posts, among others uses. The strands in PSL are clipped veneer elements having a least dimension of not more than 0.25 inches (6.4 mm) and an average length of at least 300 times this least dimension. It is a member of the structural composite lumber (SCL) family of engineered wood products.

W

WParticle board, also known as chipboard, is an engineered wood product manufactured from wood chips or jute-stick chips and a synthetic resin or other suitable binder, which is pressed and extruded. Particle board is often confused with oriented strand board, a different type of fiberboard that uses machined wood flakes and offers more strength.

W

WPerforated hardboard is tempered hardboard which is pre-drilled with evenly spaced holes. The holes are used to accept pegs or hooks to support various items, such as tools in a workshop. Peg-Board is an expired trademark used as a brand name by the Masonite Corporation, first used in 1962, which is often used as a generic term for perforated storage boards made of hardboard, wood, metal, or other material. It is commonly used in retail settings along with steel rods sticking out to hold peggable products such as bagged potato chips, printer ink, and action figures.

W

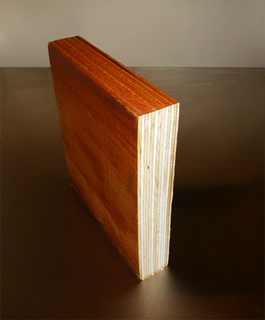

WPlywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which include medium-density fibreboard (MDF) and particle board (chipboard).

W

WThermally modified wood, is wood that has been modified by a controlled pyrolysis process of wood being heated in absence of oxygen inducing some chemical changes to the chemical structures of cell wall components in the wood in order to increase its durability. Low oxygen content prevents the wood from burning at these high temperatures. Several different technologies are introduced using different media including nitrogen gas, steam and hot oil.

W

WWood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) such as PE, PP, PVC, or PLA.