W

WSpinning is an ancient textile art in which plant, animal or synthetic fibres are drawn out and twisted together to form yarn. For thousands of years, fibre was spun by hand using simple tools, the spindle and distaff. It was only with the invention of the spinning wheel in the Islamic world circa 1030, and its subsequent introduction to China, India and Europe in the High Middle Ages, that the output of individual spinners dramatically increased. Mass production later arose in the 18th century with the beginnings of the Industrial Revolution. Hand-spinning remains a popular handicraft.

W

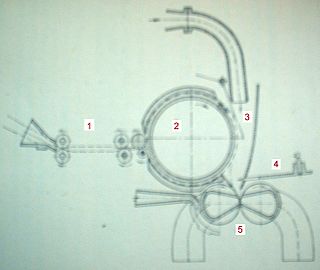

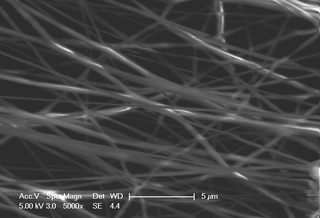

WAlternating current electrospinning is a fiber formation technique to produce micro- and nanofibers from polymer solutions under the dynamic drawing force of the electrostatic field with periodically changing polarity. The main benefit of alternating current electrospinning is that multiple times higher productivities are achievable compared to widely used direct current electrospinning setups.

W

WBarnängens manufaktur, was a textile factory in the Barnängen area in Södermalm in Stockholm in Sweden, active from 1691 until 1826. Alongside its main rival Pauliska manufakturerna, it was the biggest factory in Stockholm during the 18th-century, and during the 1780s, it employed more people than any other business in the city, the majority of whom were women. The factory has been fictionalized in the novel Vävarnas barn by Per Anders Fogelström from 1981.

W

WBynum is an unincorporated community in northeastern Chatham County, North Carolina, United States on the banks of the Haw River. Bynum is 5 miles north of Pittsboro, North Carolina and 11 miles south of Chapel Hill, North Carolina. It is also known as Bynum Mill Village or Bynum Mill Hill.

W

WCarding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with card clothing. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing.

W

WChiffon (French: [ʃi.fɔ̃];, shif-ON is a lightweight, balanced plain-woven sheer fabric, or gauze, like gossamer, woven of alternate S- and Z-twist crepe yarns. The twist in the crepe yarns puckers the fabric slightly in both directions after weaving, giving it some stretch and a slightly rough feel.

W

WWilliam Cockerill (1759–1832) was a British inventor, entrepreneur, and industrialist. Designing and producing machines for new industrial textile manufacturing, he is best known for having established a major manufacturing firm in what is now Liège Province of modern-day Belgium. He is widely considered to have been instrumental in spreading the Industrial Revolution in Continental Europe

W

WColdharbour Mill, near the village of Uffculme in Devon, England, is one of the oldest woollen textile mills in the world, having been in continuous production since 1797. The mill was one of a number owned by Fox Brothers, and is designated by English Heritage as a Grade II* listed building.

W

WCombing is a method for preparing carded fibre for spinning. Combing is divided into linear and circular combing. The Noble comb is an example of circular combing. The French comb is an example of linear combing. The process of combing is accompanied by gilling, a process of evening out carded or combed top making it suitable for spinning. Combing separates out short fibres by means of a rotating ring or rectilinear row of steel pins. The fibres in the 'top' it produces have been straightened and lie parallel to each other. When combing wool, the discarded short fibres are called noils, and are ground up into shoddy.

W

WA cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

W

WCotton-spinning machinery refers to machines which process prepared cotton roving into workable yarn or thread. Such machinery can be dated back centuries. During the 18th and 19th centuries, as part of the Industrial Revolution cotton-spinning machinery was developed to bring mass production to the cotton industry. Cotton spinning machinery was installed in large factories, commonly known as cotton mills.

W

WCromford Mill is the world's first water-powered cotton spinning mill, developed by Richard Arkwright in 1771 in Cromford, Derbyshire, England. The mill structure is classified as a Grade I listed building. It is now the centrepiece of the Derwent Valley Mills UNESCO World Heritage Site, and is a multi-use visitor centre with shops, galleries, restaurants and cafes.

W

WFriction Spinning or Dref Spinning is a textile technology that suitable for spinning coarse counts of yarns and technical core-wrapped yarns. Dref yarns are bulky, with low tensile strength making them suitable for blankets and mop yarns, they can be spun from asbestos, carbon fibres and make filters was water systems. Yarns such as Rayon and Kevlar can be spun using this method. The technology was developed around 1975 by Dr. Ernst Fehrer.

W

WElectrospinning is a fiber production method which uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers. The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product.

W

WHaarlem Mill, on the River Ecclesbourne in Wirksworth, Derbyshire, was an early cotton mill. Built by Richard Arkwright, it was the first cotton mill in the world to use a steam engine, though this was used to supplement the supply of water to the mill's water wheel, not to drive the machinery directly.

W

WThe Handweavers Guild of America (HGA) is an association of fiber artists founded in the U.S. in 1969. The guild provides educational programs, conferences, and scholarships for fiber arts students. It publishes the quarterly journal Shuttle Spindle & Dyepot.

W

WHoward & Bullough was a firm of textile machine manufacturers in Accrington, Lancashire. The company was the world's major manufacturer of power looms in the 1860s.

W

WThe Irish Guild of Weavers, Spinners, and Dyers (IGWSD) is an organisation for the promotion and preservation of hand weaving, spinning and dyeing in Ireland.

W

WLakshmi Machine Works Limited is India's largest textile machinery and CNC Machine Tool manufacturers, based in Coimbatore founded by Dr. G.K. Devarajulu. It started its operation in 1962 in Periyanaickenpalayam in Coimbatore city with technical collaboration with Swiss-based textile machinery manufacturer Rieter for textile machines and German based Steel & Ammunition major Krupp. In mid 1980's the company bought over its Coimbatore based longtime rival and an older Textile & Engineering giant Textool. The company is promoted and owned by the Lakshmi Mills family.

W

WIn spinning, a lazy kate is a device used to hold one or more spools or bobbins in place while the yarn on them is wound off from the side of the bobbin. Typically, a kate consists of multiple rods, which allow the bobbins to spin. Tensioned kates have a band that loops over the bobbins to prevent them from spinning freely. Some spinning wheels have built-in kates, although these tend to be more cumbersome to use than free-standing ones.

W

WJohn Lees of Turf Lane, Royton, Lancashire was an English inventor who made a substantial improvement to machinery for carding cotton.

W

WLong draw is the spinning technique used to create woolen yarns. It is spun from carded rolags. It is generally spun from shorter stapled fibers. Long draw spun yarns are light, lofty, stretchy, soft, and full of air, thus they are good insulators, and make good knitting yarns.

W

WMarvel's Mill on the River Nene in Northampton, England, was the world's second factory for spinning cotton, the first to be operated as a water mill, and the first to be driven by an inanimate power-source. Opened by Edward Cave in 1742, it was one of the Paul-Wyatt cotton mills that used the roller spinning machinery invented by Lewis Paul and John Wyatt, which had first been used in their Upper Priory Cotton Mill in Birmingham in the summer of 1741.

W

WSir Richard Arkwright's Masson Mill is a water-powered cotton spinning mill situated on the west bank of the River Derwent in Matlock Bath, Derbyshire in England. This mill was built in 1783. It forms part of the Derwent Valley Mills, a World Heritage Site. Nearby is Willersley Castle, the house Richard Arkwright built for himself within the parish of Matlock.

W

WMule spinners' cancer or mule-spinners' cancer was a cancer, an epithelioma of the scrotum. It was first reported in 1887 in a cotton mule spinner. In 1926, a British Home Office committee strongly favoured the view that this form of cancer was caused by the prolonged action of mineral oils on the skin of the scrotum, and of these oils, shale oil was deemed to be the most carcinogenic. From 1911 to 1938, there were 500 deaths amongst cotton mule-spinners from cancer of the scrotum, but only three amongst wool mule spinners.

W

WThe Ontario Handweavers & Spinners (OHS) is a non-profit organization based in Ontario, Canada that helps individuals interested in the fiber crafts to communicate and develop their skills, including weaving, spinning and dying, basket makers, braiders, tablet weavers and paper makers. The OHS communicates to its members through a quarterly newsletter, Fibre Focus, provides educational programs in spinning and weaving, provides scholarships and organizes several seminars or conferences each year.

W

WOpen-end spinning is a technology for creating yarn without using a spindle. It was invented and developed in Czechoslovakia in Výzkumný ústav bavlnářský / Cotton Research Institute in Ústí nad Orlicí in 1963.

W

WThe Paul-Wyatt cotton mills were the world's first mechanised cotton spinning factories. Operating from 1741 until 1764 they were built to house the roller spinning machinery invented by Lewis Paul and John Wyatt. They were not very profitable but they span cotton successfully for several decades.

W

WLewis Paul was the original inventor of roller spinning, the basis of the water frame for spinning cotton in a cotton mill.

W

WRing spinning is a method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

W

WA rolag is a roll of fibre generally used to spin woollen yarn. A rolag is created by first carding the fibre, using handcards, and then by gently rolling the fibre off the cards. If properly prepared, a rolag will be uniform in width, distributing the fibres evenly. The word derives from the Scottish Gaelic word for a small roll.

W

WA roving is a long and narrow bundle of fiber. Rovings are produced during the process of making spun yarn from wool fleece, raw cotton, or other fibres. Their main use is as fibre prepared for spinning, but they may also be used for specialised kinds of knitting or other textile arts.

W

WRoyal Mill, which is located on the corner of Redhill Street and Henry Street, Ancoats, in Manchester, England, is an early-twentieth-century cotton mill, one of the last of "an internationally important group of cotton-spinning mills" sited in East Manchester. Royal Mill was constructed in 1912 on part of the site of the earlier McConnel & Kennedy mills, established in 1798. It was originally called New Old Mill and was renamed following a royal visit by King George VI and Queen Elizabeth in 1942. A plaque commemorates the occasion. The Ancoats mills collectively comprise "the best and most-complete surviving examples of early large-scale factories concentrated in one area".

W

WFat draw is the spinning technique used to create worsted yarns. It is spun from combed roving, slivers or wool top – anything with the fibers all lined up parallel to the yarn. It is generally spun from long stapled fibers. Short draw spun yarns are smooth, strong, sturdy yarns, and dense. Short draw spun yarns also tend to not be very elastic. These characteristics make them good for use in weaving.

W

WThe spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

W

WThe spinning jenny is a multi-spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England.

W

WThe spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute. It was invented between 1775 and 1779 by Samuel Crompton. The self-acting (automatic) mule was patented by Richard Roberts in 1825. At its peak there were 50,000,000 mule spindles in Lancashire alone. Modern versions are still in niche production and are used to spin woollen yarns from noble fibres such as cashmere, ultra-fine merino and alpaca for the knitware market.

W

WA wool staple is a cluster or lock of wool fibres and not a single fibre.

W

WThe throstle frame was a spinning machine for cotton, wool, and other fibers, differing from a mule in having a continuous action, the processes of drawing, twisting, and winding being carried on simultaneously. It "derived its name from the singing or humming which it occasioned," throstle being a dialect name for the song thrush.

W

WIn the textile industry, a tow is a coarse, broken fibre, removed during processing flax, hemp, or jute and separated from the shives. Flax tows are often used as upholstery stuffing and oakum. Tows in general are frequently cut up to produce staple fibre. The very light color of flax tow is the source of the word "towhead", meaning a person with naturally light blonde hair.

W

WThe water frame is a spinning frame that is powered by a water-wheel. Water frames in general have existed since Ancient Egypt times. Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread; this was first used in 1765. The Arkwright water frame was able to spin 96 threads at a time, which was an easier and faster method than ever before. The design was partly based on a spinning machine built for Thomas Highs by clockmaker John Kay, who was hired by Arkwright. Being run on water power, it produced stronger and harder yarn than the then-famous "spinning jenny", and propelled the adoption of the modern factory system.